Core Advantages

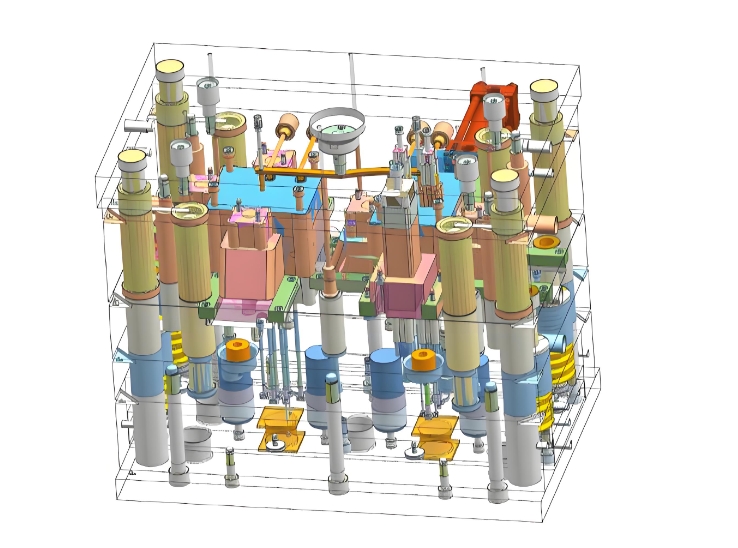

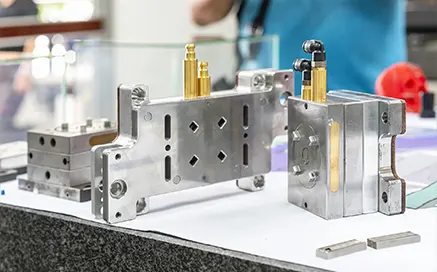

Full-process manufacturing coverage

The business spans the entire product lifecycle from concept to final product, including prototyping, CNC machining, mold manufacturing, injection molding, high-pressure die casting, casting, sheet metal processing, stamping, extrusion, product assembly, and various surface treatments, providing customers with comprehensive manufacturing services.

- Possesses self-owned multiple factories and a scientific production management system to underpin integrated operations.

- Integrates diverse processes to achieve end-to-end seamless connection between design and production stages.

- Significantly shortens product development cycles, improves production efficiency, and enables faster market deployment for customers.

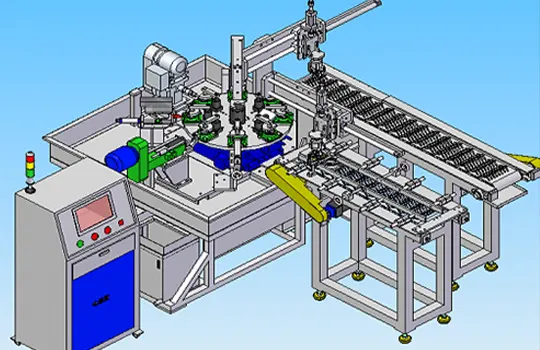

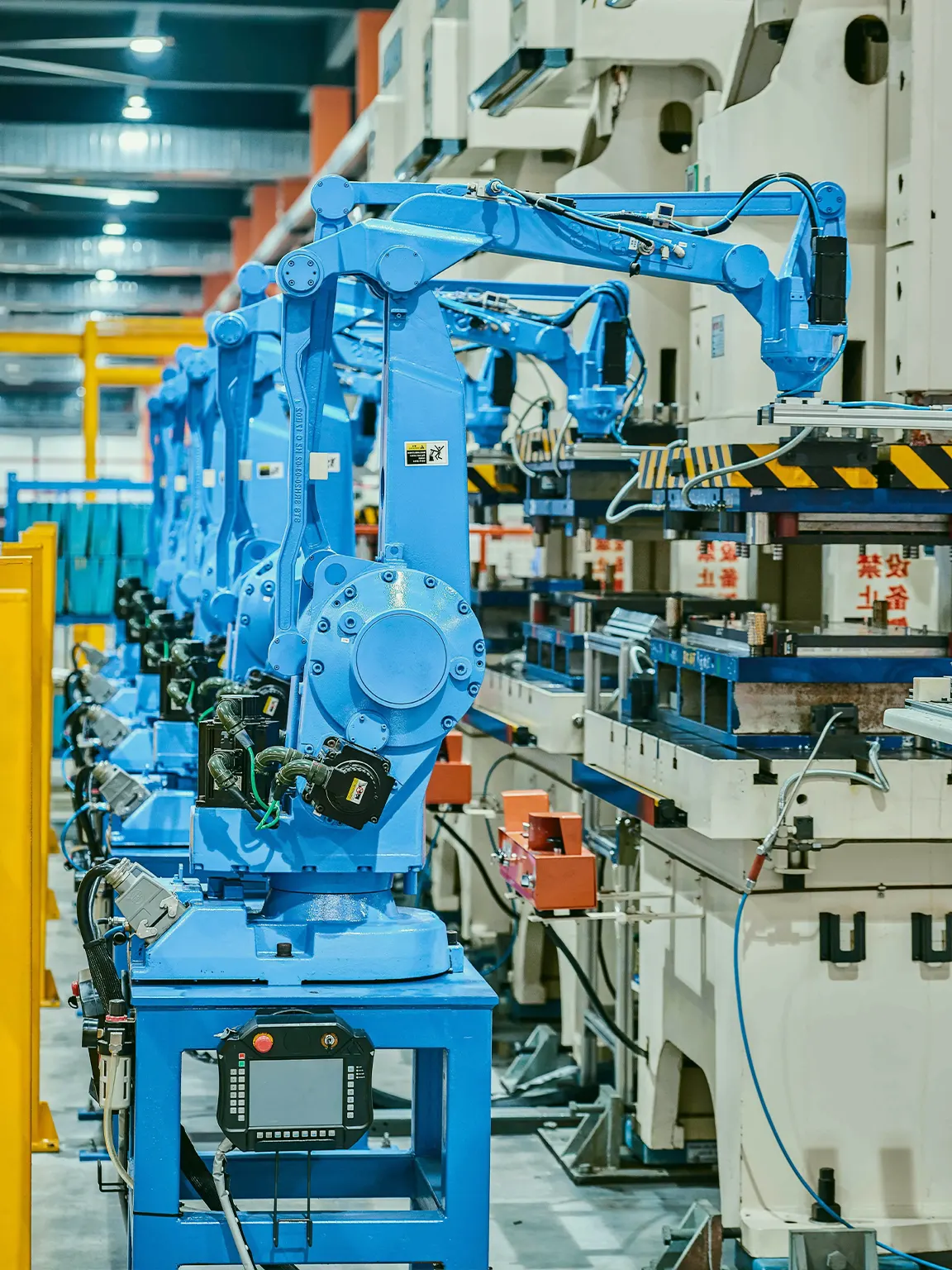

Abundant equipment quantity and variety

It owns over 300 CNC machines (including 3-axis, 4-axis, and 5-axis), 76 injection molding machines (single-color, two-color, and three-color), 45 extrusion, sheet metal, and stamping machines, as well as numerous imported inspection devices such as German Weiss CMM and Japanese CMM, providing a solid equipment foundation for high-precision and large-scale production.

- Achieves ±0.002mm precision, perfect for complex, high-tolerance parts.

- Ensures full-process traceability and strict control with PPAP.

- Conducts 100% pre-shipment inspections, guaranteeing reliability and eliminating quality worries.

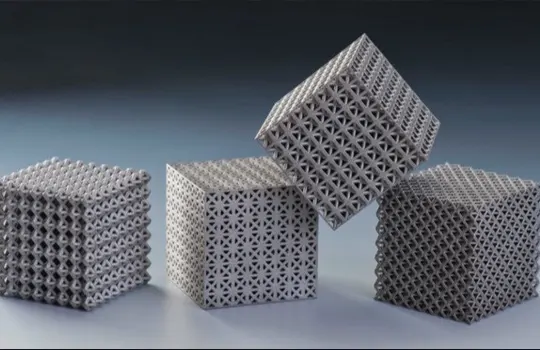

Fast prototype development

It can quickly transform customers' ideas into realistic prototypes through various methods such as 3D printing, vacuum casting, CNC machining, and rapid injection molding, enabling fast testing and verification of parts, helping customers smoothly transition from the concept stage to the market, and accelerating product development.

- No MOQ, catering to small - batch custom and large - scale mass production.

- Free sample testing, one - week mold delivery to speed up project development.

- Fast, bridge, and mass - production molds help cut tooling costs and fit various production stages.

Abundant industry experience

Founded in 2001, with over 20 years of expertise in mold manufacturing and injection molding, the company boasts a robust engineering team (feasibility solutions, project management, quality control). This team ensures project quality, delivery, and cost-effectiveness from the client’s perspective, empowering customers to thrive in competitive markets.

- Serves 5,000+ customers across 40+ countries, with 700M+ parts produced—proven market presence and capacity.

- Delivers quality services worldwide through a responsibility- and integrity-driven approach, fostering lasting collaborations.

- Offers localized market promotion and trial support in Asia, backed by a robust global service network for comprehensive capabilities.

Solve Your Biggest Sourcing and Manufacturing Challenges

AI Production System

Fully intelligent AI-driven smart factory processing, precise and rigorous.

Full-process service

One-stop full-process service to shorten the cycle.

Fast multi-process delivery

Efficient collaboration of multiple processes for ultra-fast delivery.

Full-course control

Full-course quality control for quick and reliable results.

What’s New at Protolabs?

How to Work With Us

Design and Engineering Support

We offer both automated and live manufacturing support. With every quote, you get free interactive manufacturability analysis to quickly improve part design, but if you have additional questions, applications engineers are always available to talk through your project at

IDEATION

Guided Expertise

✓Manufacturability Guidance

✓Material & Finishing Expertise

✓Cost, Quality, Compliance

Our Technology

✓Instant DFM

✓Materials.AI

✓2D drawings generator & annotation

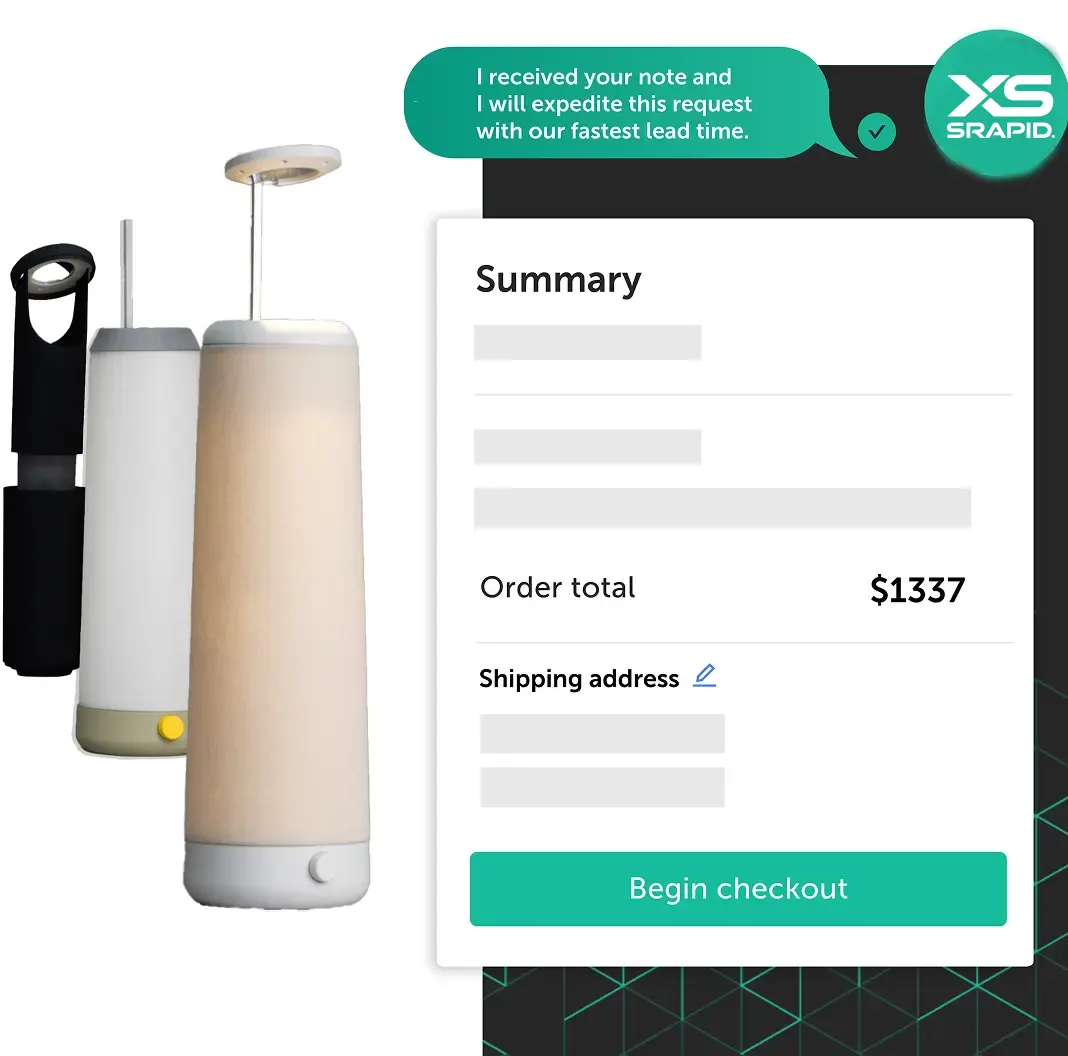

PRODUCT DEVELOPMENT

Guided Expertise

✓Expedited Prototyping

✓Finished Parts and Assemblies for NPD and Testing

✓No Minimum Order Quantities

✓Easily Scale from Ideation to Production

Our Technology

✓Instant Quoting

✓Traceability for Test Hardware in Platform

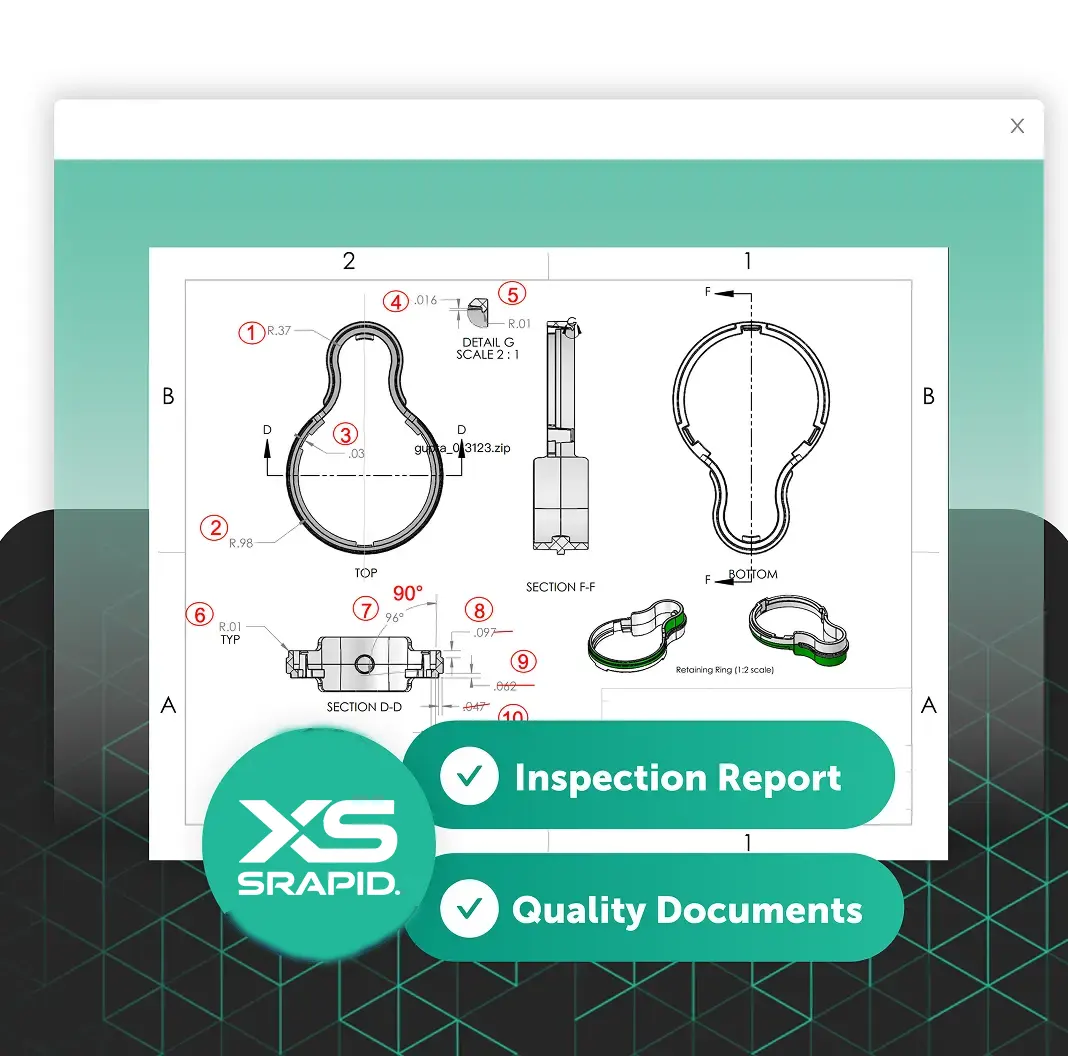

MANUFACTURING CENTER OF EXCELLENCE SELECTION

Guided Expertise

✓RFQ for Complex Programs

✓FQuality Management System

Our Technology

✓Easily Configure for Time v Cost

✓Project Traceability

GLOBAL SUPPLY CHAIN OPTIMIZATION

Guided Expertise

✓BOM Cost Down

✓Program Management

✓Capacity Forecasting

Our Technology

✓Quality Documentation

✓Lowest Landed Cost Support

✓Logistics Optimization

✓Lead Time Optimizer

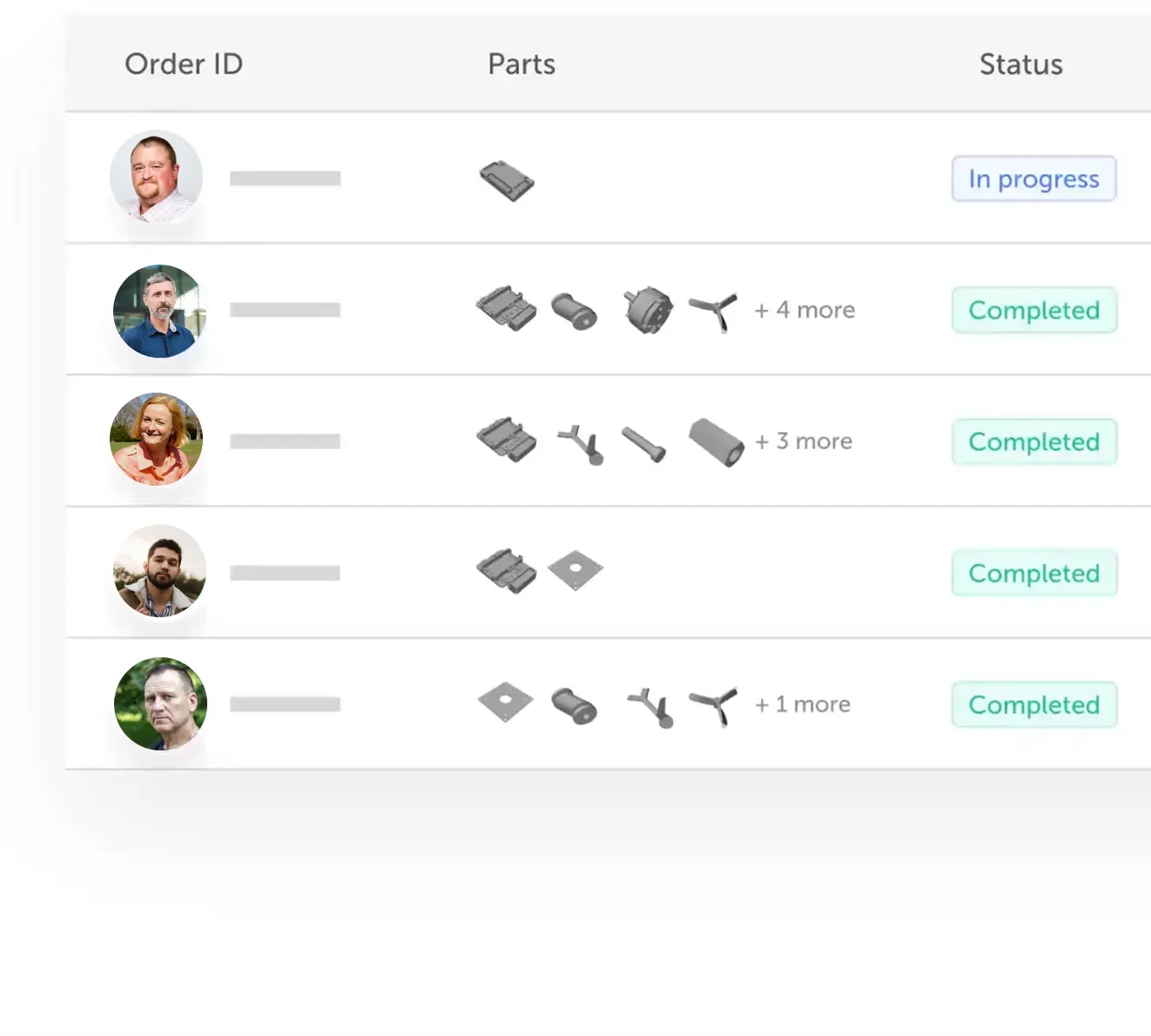

✓Automated Order Status

SUPPLY CHAIN PLATFORM

Guided Expertise

✓Complex BOMs, including

✓Assembly & Finishing

✓Sourcing and Supplier Management

✓Global Logistics, Compliance, Quality

✓Tariff Management

Our Technology

✓Material Sourcing & Testing Certs

✓Lowest Landed Cost Support

✓Team Workspaces

✓Procure-to-Pay System Integration

✓Virtual Inspection

✓Exception Triage

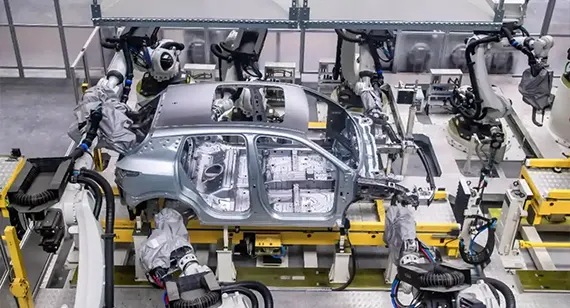

Major Industries Served

We work with more than 90% of Fortune 100 companies from our target industries.