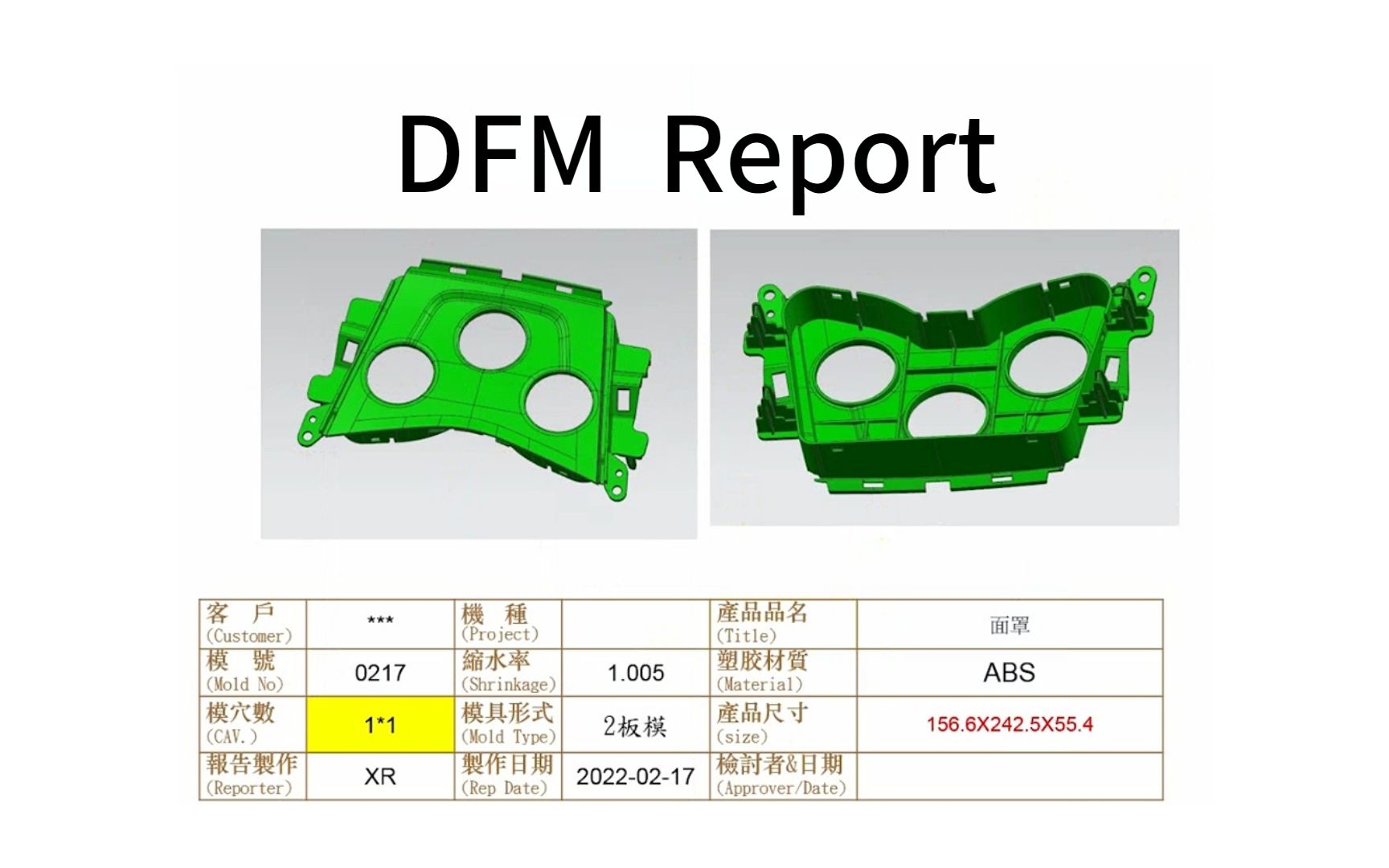

Design for Manufacturing (DFM) Analysis

When requesting a quote through our online quoting system, you will receive manufacturing analysis and pricing.

How our manufacturing analysis can improve quality of injection-molded parts:

- Identifies thick walls

- Identifies features with insufficient draft

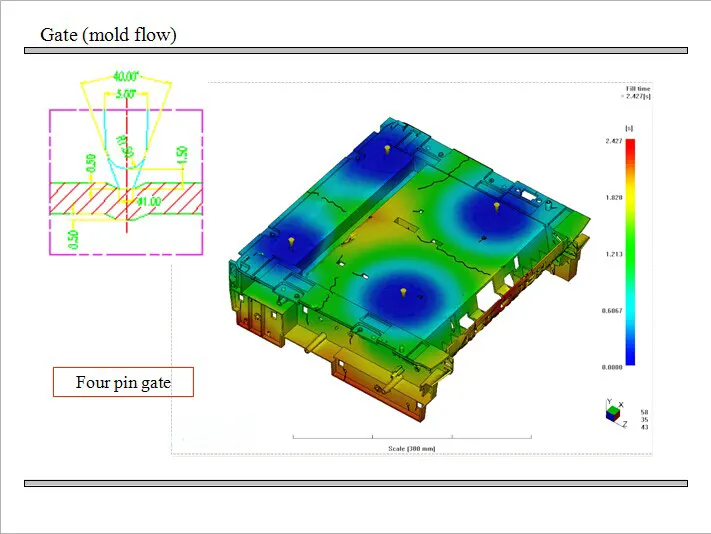

- Mold flow analysis

- Select gate location

- Select ejector pin location

Scientific Molding: Consistently Delivering Quality Parts

We use scientific, or decoupled, injection molding to produce consistent parts for our customers. Each project has an optimized, documented process that ensures uniformity in every run. Modifications are tracked for traceability across runs. Scientific molding guarantees consistency in the process, meeting specific resin and dimensional requirements whether the part is re-run or ordered later. By controlling fill, pack, and hold, we ensure each part matches the previous one, providing benefits of higher quality and consistent inspection reports for our customers.

Design Support from Injection Molding Experts

Consultative Design Services: Work directly with an injection molding applications engineer to improve the moldability of your design. Think of it like having your very own injection molding consultant on your team. During this process, our applications engineer will collaborate with you to understand your design goals, review the manufacturing analysis provided in your online quote, and make changes to the 3D CAD file.

XS Proposed Revision (PPR): In some instances, we can provide a second CAD model to you—called a XS Proposed Revision (PPR). This is a new CAD file with changes already made. The revised model can be used immediately or you can transfer the modifications to the original model. Following the DFM analysis, and, in some cases, the PPR, once the part has been approved,XS moves into the final step before actual production—the digital preparation.

Inspections for Injection-Molded Parts

We offer several quality inspection reports for injection molding orders. Depending on your project requirements you can choose from the following reports:

- CTQ Partial FAI

- CTQ DIR with Capability Study

- Production Part Approval Process (PPAP)

- Digital Inspection Report / Full FAI

- Custom Inspection

Injection Molding Inspection Reports

As part of the XS standard, we measure up to four plane-to-plane and outside diameter dimensions based on your CAD model (X, Y, Z) to quoted tolerances. We automatically define these quality control checks and perform the measurements on a sampling of parts.

In addition, we provide a wide range of other quality documentation. Compare the benefits of each inspection report to see which is best suited for your project needs.

How are Part Dimensions Measured?

We use industry standard coordinate-measuring machines (CMM)—calipers and pin guages—just as you would expect from an industry leading manufacturing partner. What differentiates our process is that we’ve applied patented automation technology to our CMMs to enable in-process inspection with no additional cost or lead time.

Parts are measured at an equidistant cadence of n/30 where n = total part order quantity. Along with the measurement data from each part, the Capability Report will also provide the average measurement, standard deviation, and a Process Capability Index (Cpk) value for all critical dimensions.

Critical to Quality (CTQ)

| CTQ Partial FAI | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| CTQ with Capability Study | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

*Excludes: Thermoplastic elastomers (TPU, TPV, TPO, etc.) and Liquid Silicone Rubber (LSR).

Additional Inspection Reports

| Digital Inspection Report | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Production Part Approval Process | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Additional Quality Capabilities

Medical Molding Capabilities

We do offer ISO 13485 injection molding capabilities through trusted partners.

Custom Inspection

Additional inspection options are available, tailored to your requirements, allowing verification of numerous critical dimensions.

Contact your account representative to request a custom inspection.