Post-Processing for CNC Machining

Evaluate standard surface finishes for CNC machined parts as well as advanced capabilities to improve durability, surface finish, and add color.

Certifications: ISO 9001:2015 | AS9100D | ITAR

Standard Finishes

Choose from three standard surface finish options for CNC machined parts.

Edges broken (tool marks visible)

Edges deburred with visible toolmarks.

Materials: Plastic, Metals

Cost: $

Edges broken and light bead blast

Edges deburred with light bead blast.

Materials: Metals

Cost: $$

Leave sharp (tool marks visible)

Edges left sharp (tool marks visible) should be handled with care.

Materials: Metals

Cost: $

Quick-Turn Coating Options

Anodizing and chromate coating options are available for quick-turn parts that ship within four days.

Anodizing Type II

MIL-A-8625

Colors: Black, Clear

Cost: $$

Anodizing Type III (Hardcoat)

MIL-A-8625

Colors: Black

Cost: $$$

Chromate Type II (Non-Hexavalent)

MIL-DTL-5541

Colors: Clear

Cost: $$

Visit our coating page to see more details about anodizing and chromate conversion coating.

Advanced Post-Processing Options for CNC Machining Parts

Through myRapid and Protolabs Network, access a broad range of post-processing capabilities to meet your part’s exact specifications.

| Description | Materials | Factory | myRapid | Network | |

|---|---|---|---|---|---|

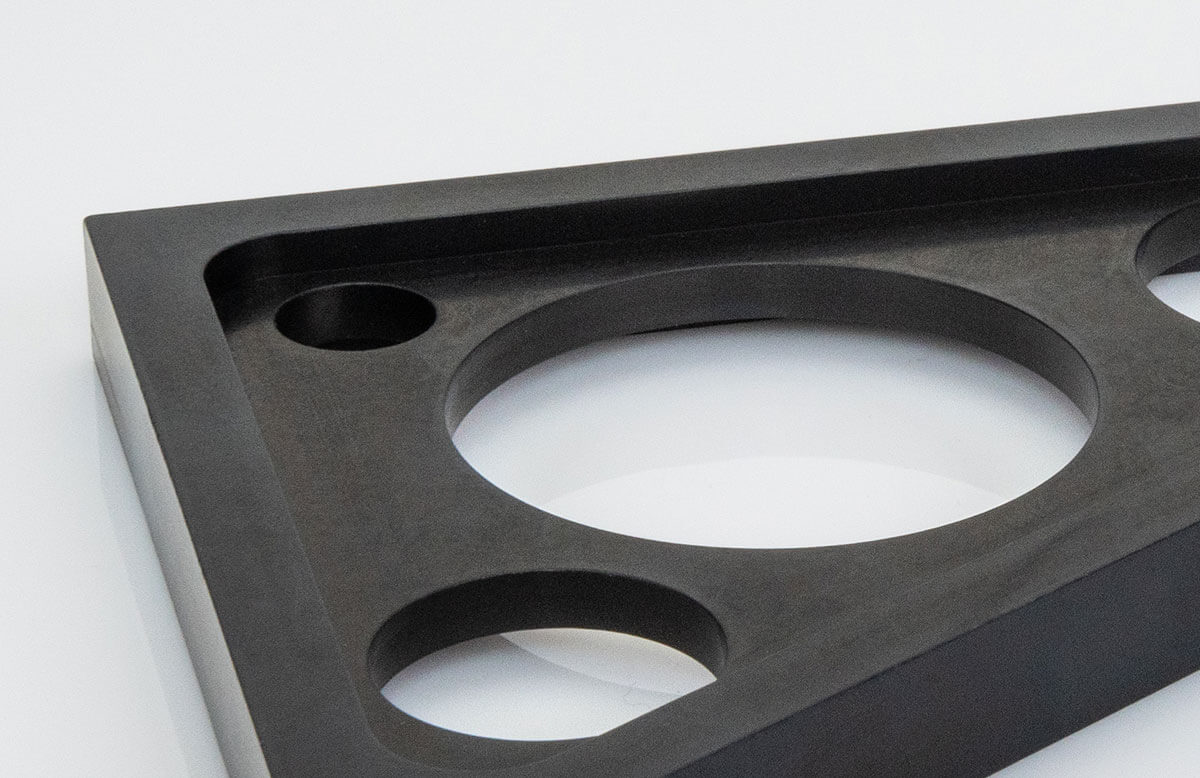

| Bead Blast | Light bead blast to provide uniform finish and light texture | Metals | X | X | X |

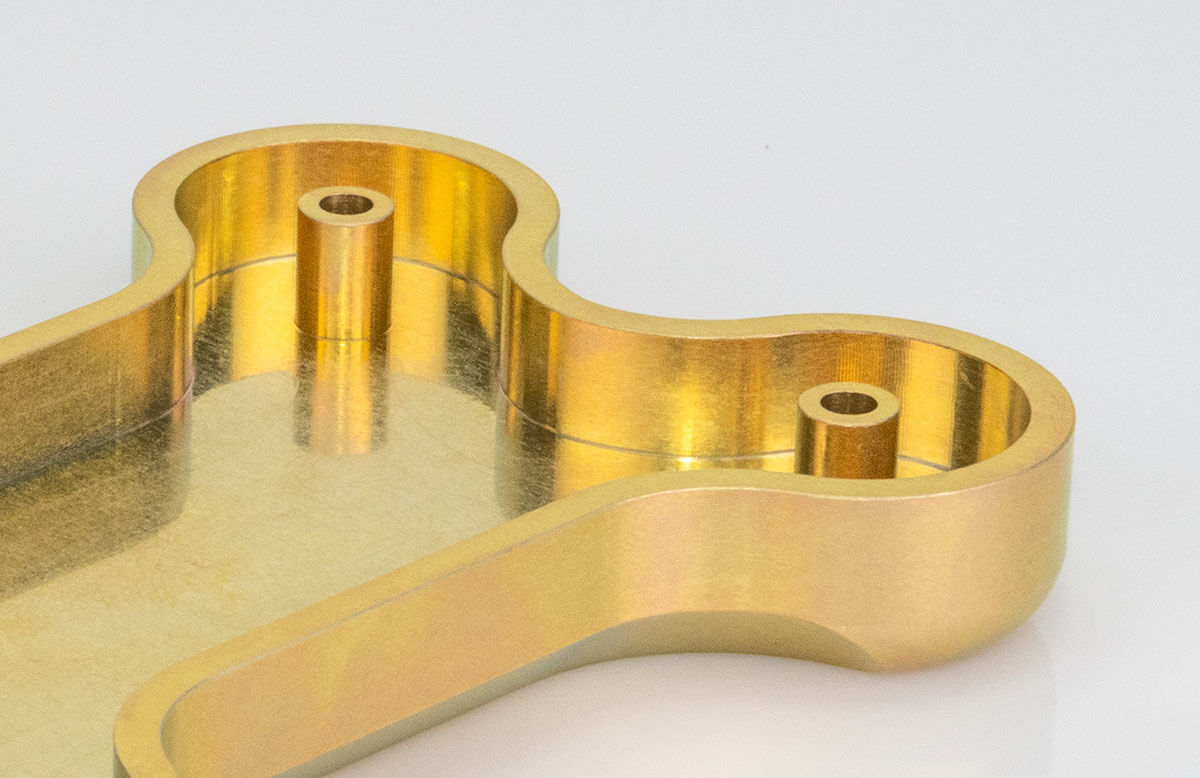

| Anodizing | Type I, II, and III finishes are available to improve part durability and add color | Aluminum Titanium |

X | X | X |

| Chromate Coating | Improve corrosion resistance, add electrical connectivity, and the ability to better paint parts | Metals | X | X | X |

| Electroless Nickel Plating | A wear-, abrasion-, and corrosion resistant finish that is compatible with aluminum, stainless steel, and mild steel | Aluminum Steel |

X | X | |

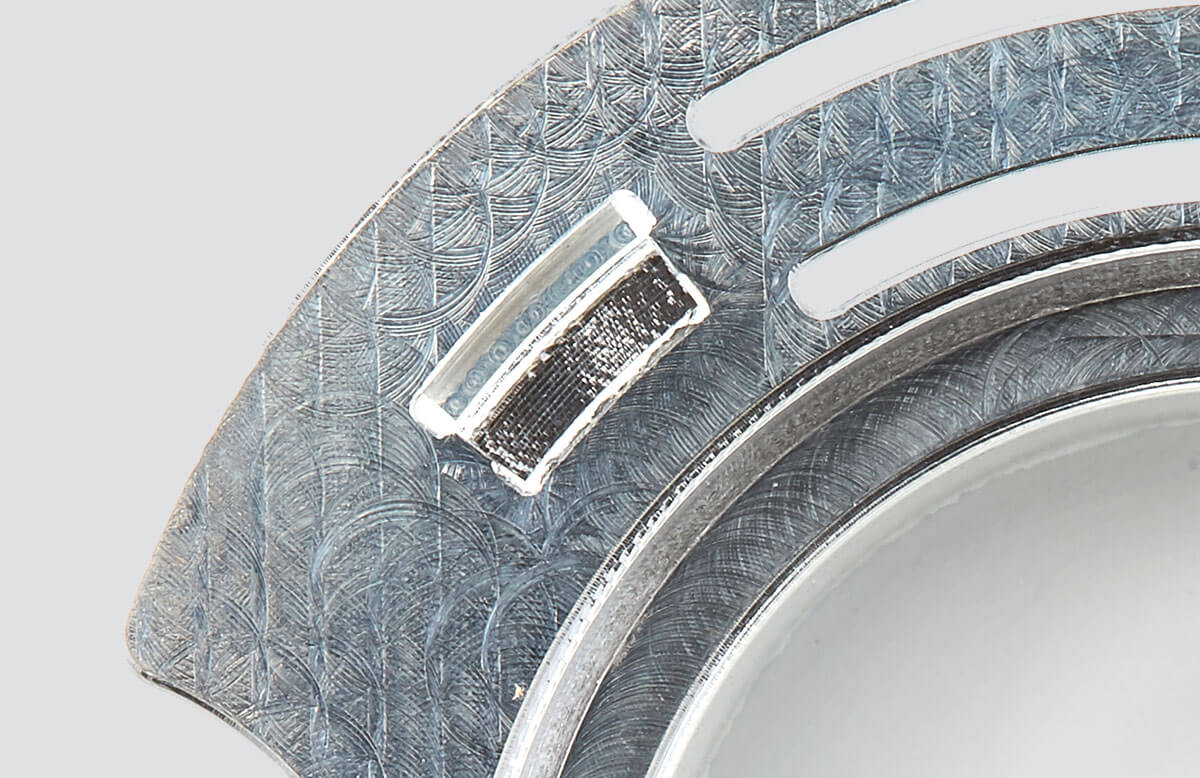

| Part Marking | Laser engraving or pad printing to add labeling and other text to parts | Metals Plastics |

X | X | |

| Passivation | Enhance durability and corrosion resistance of metal parts | Metals | X | X | |

| Powder Coating | Add custom color to parts while improving durability | Metals | X | X | |

| Press Fit Hardware | Incorporate off-the-shelf hardware components to facility assembly | Metals | X | X | |

| Silk Screening | Add design elements or labels to parts | Metals | X | X | |

| Brushing | Achieve uniform, satin-like surface finish | Stainless Steel | X | ||

| Polishing | Create mirror-like finishes on metal parts | Metals | X | ||

| Black Oxide | Improve corrosion resistance | Metals | X | ||

| Brushed + Electropolishing | This combination of processing results in easy-to-clean parts that are corrosion resistant | Metals | X |