Quality is in Our Work Standards, and our DNA

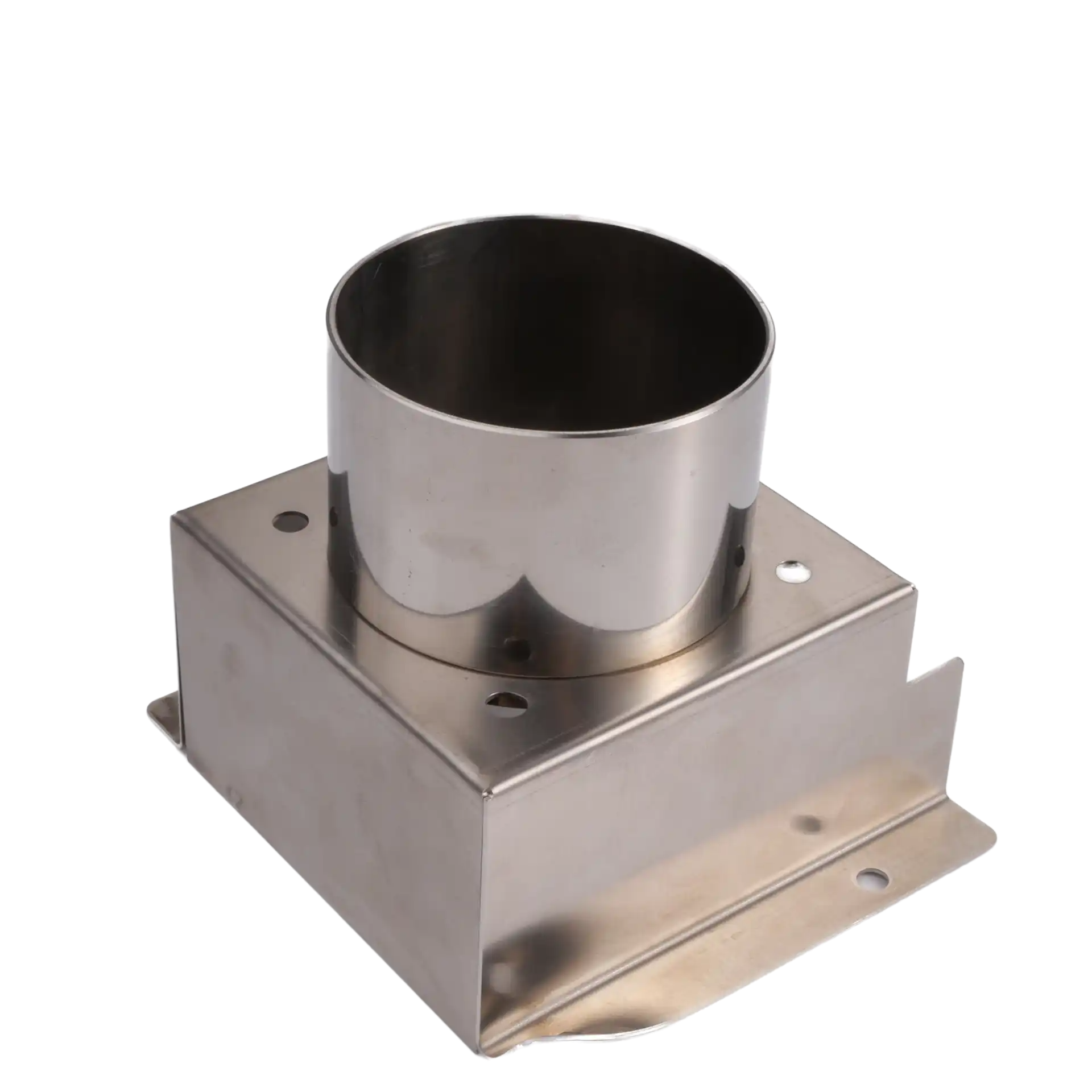

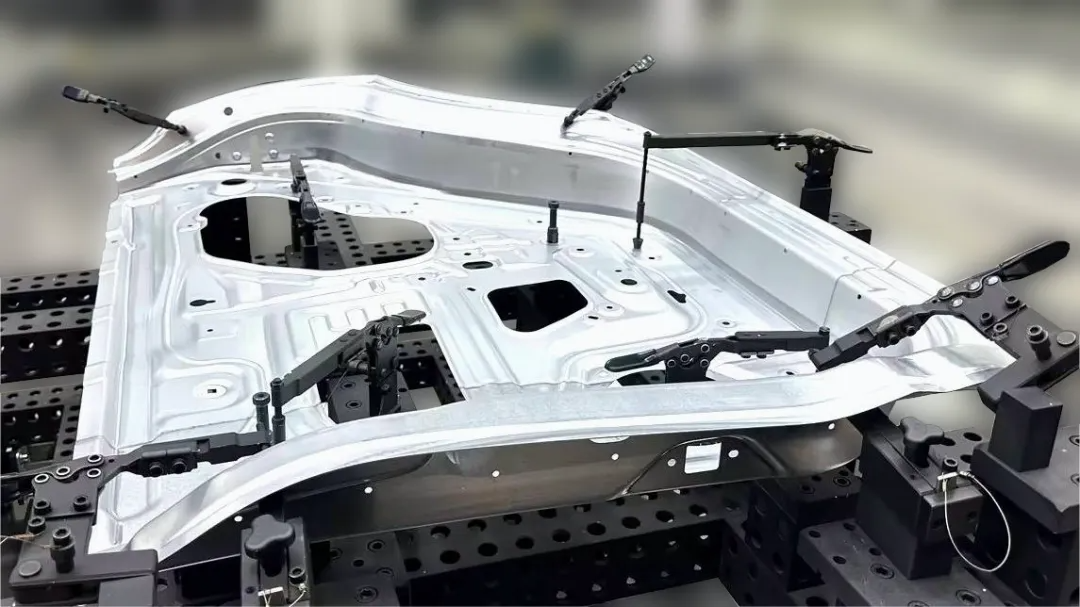

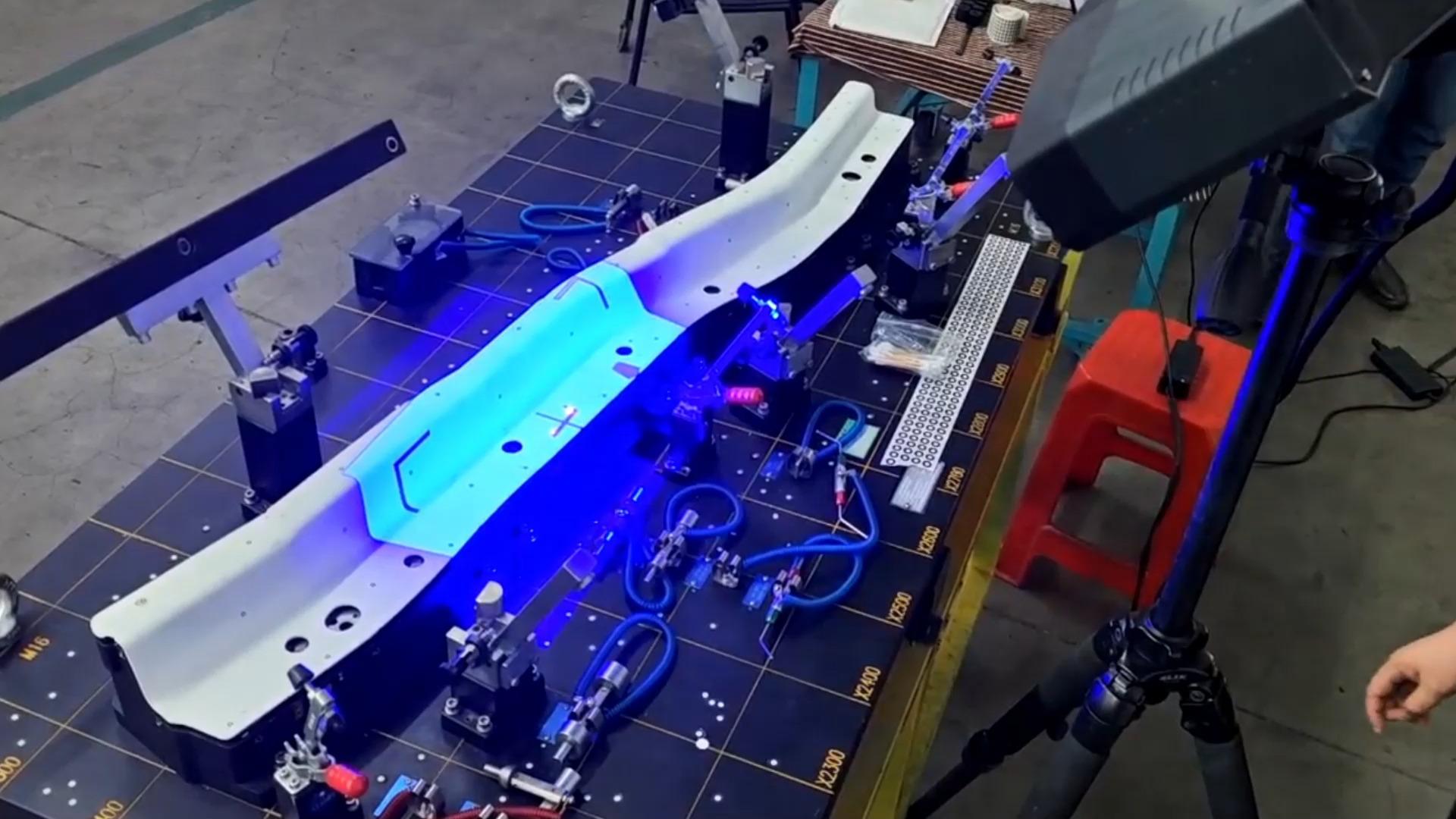

Our mission is to deliver great parts every time. To do that, we use clearly documented work standards and procedures. To minimize escapes, our team of skilled fabricators performs in-process quality checks on every unique geometry. Once the part is completed, our quality control experts take over to visually and dimensionally inspect the physical part to ensure consistency with your 3D model (or print, if necessary).

Inspection Documentation for Sheet Metal Projects

We offer multiple forms of quality inspection documentation and reports for sheet metal fabrication orders. Depending on your project requirements, you can choose from these reports within your online quote:

- Dimensional Inspection Report

- First Article Inspection (2D drawing required)

- Certificate of Conformance

- Material Certification

- Finish Certification

Here's more about each of these reporting options so you can determine which is the best choice for your project:

这是标题

| Certificate of Conformance | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Dimensional Inspection Report (DIR) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| First Article Inspection (FAI) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Design for Manufacturing (DFM) Analysis

When requesting a quote through our digital quoting platform, you will receive both manufacturability analysis and pricing. This important first step in the digital manufacturing process enables you to test multiple designs simultaneously, thereby achieving design validation sooner, which saves time in the development cycle.

Our manufacturing analysis can improve the quality of sheet metal parts by:

- Identifying non-uniform part thicknesses

- Validating a feature's (e.g. cutouts, holes) proximity to bends

- Verifying hardware insert and sheet metal material compatibility

- Analyzing flange length

- Evaluating bend radius tooling

Design Support from Sheet Metal Experts

Our experts are available to review your sheet metal design and discuss any questions you may have. Choose from the two design support options below:

Consultative Design Service

Work directly with a sheet metal applications engineer to improve the manufacturability of your design. It's like having a personal sheet metal fabrication consultant on your team. During the process, our applications engineer will collaborate with you in order to understand your design goals, review the manufacturing analysis provided in your online quote, and make any necessary changes to the CAD file.

Design Review

Discuss your design with a sheet metal applications engineer to answer any manufacturability questions your might have. Common design review topics include optimizing for cost, feature location and spacing, and questions about press brake forming.