Jump to Section

→ Capabilities

→ Materials

→ Surface Finishes

→ About Carbon DLS 3D Printing

Beyond Prototyping

When your project requires advanced mechanical properties beyond stereolithography (SLA) and XS, explore our advanced photopolymer materials unlocked by Carbon DLS and Axtra3D Hybrid PhotoSynthesis (HPS) technologies. HPS leverages the best features of our popular Carbon digital light synthesis (DLS) printers, such as speed, near-isotropic parts, and smooth surface finish, but adds the greater speed and higher resolution of stereolithography (SLA). HPS and Carbon DLS are worth a close look for manufacturing of your project.

Hybrid PhotoSynthesis (HPS)

HPS technology integrates both a precision laser and a digital light processing (DLP) system to simultaneously image internal and external structures. This dual approach allows the Axtra3D printer to overcome traditional limitations and produce exceptionally detailed parts with unmatched speed and quality.

Common applications for HPS are:

- High accuracy features for testing and validation.

- Production grade parts with excellent throughput.

- Glass-like surface finishes for cosmetic prototypes.

Carbon DLS

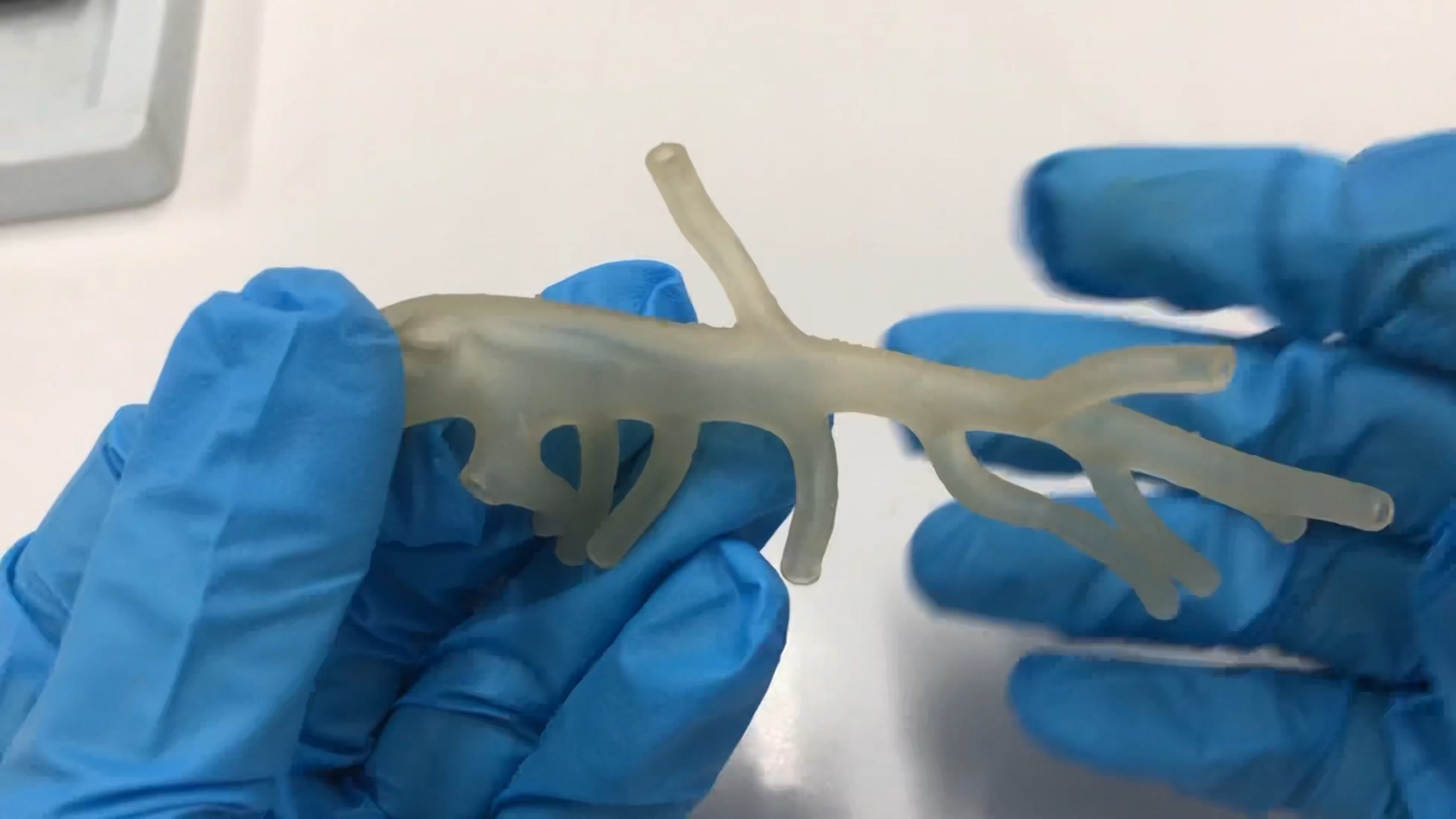

Carbon DLS (digital light synthesis) is an industrial 3D printing process that creates functional, end-use parts with mechanically isotropic properties and smooth surface finishes. You can choose from both rigid and flexible polyurethane materials to meet your application needs for high impact-resistance components.

Common application for Carbon DLS are:

- Complex designs that are challenging to mold

- Need for isotropic mechanical properties and smooth surface finish

- Production parts in materials comparable to ABS or polycarbonate

- Durable components for end use

HPS and Carbon DLS Guidelines and Capabilities

Our basic guidelines for Carbon DLS (digital light synthesis) include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| HPS | ||||||

|---|---|---|---|---|---|---|

| ||||||

Carbon DLS

|

| HPS | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon DLS

|

| Tough Black | |||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ceramic-Filled and Flame Retardant Black

Carbon DLS

|

Tough Black

Expected tolerances are +/- 0.010 in. (0.25mm) for the first inch plus 0.1% of nominal length. Keep in mind that tolerances are not guaranteed on your first build of parts, but we will work closely with you to help achieve critical dimensions. Please request critical dimensions when you upload your part, and our applications engineers will quickly review and provide feedback.Ceramic-Filled and Flame Retardant Black

For well-designed parts, tolerances in the X/Y dimension of +/-0.002 in. (0.05mm) for the first inch plus 0.1% of nominal length (0.001mm/mm), and Z dimension tolerances of +/-0.005 in. (0.01mm) for the first inch plus 0.1% of nominal length typically can be achieved. Note that tolerances may change depending on part geometry.Carbon DLS Tolerances

Expected tolerances are +/- 0.010 in. (0.25mm) for the first inch plus 0.1% of nominal length. Keep in mind that tolerances are not guaranteed on your first build of parts, however, we will work closely with you to help achieve critical dimensions. Please request critical dimensions when you upload your part, and our applications engineers will quickly review and provide feedback.| Surface Finish Options | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Taps Threaded inserts

HPS and Carbon DLS Material Options

- Tough Black (Loctite Henkel 3843)

- Ceramic-Filled (BASF 3280)

- Carbon FPU 50

- Flame Retardant Black (Arkema FR512)

Tough Black (Loctite Henkel 3843)

Tough Black (Loctite Henkel 3843) is a slow-curing, engineering-tough resin with high strength, good impact resistance and excellent surface finish. It’s great for a wide range of tooling applications such as jigs and fixtures, housings, and covers.

Primary Benefits

High impact strengthSemi-flexible

Excellent smooth and matte surface finish

Ceramic-Filled (BASF 3280)

Ceramic-Filled (BASF 3280) is a composite offering extremely high stiffness of around 10 GPa and an HDT above 536 F (280 C). This material is often used for tooling and molding.

Primary Benefits

Superior stiffnessExcellent temperature performance

High suspension stability

Ceramic-like color and feel

Carbon FPU 50 (Loctite Henkel 3843)

Carbon FPU 50 exhibits the highest elongation of any of the 3D printing thermoset resins at 200% making it the most flexible option. Available in black, it falls under the PP-like category of 3D printing resins.

Primary Benefits

Highest elongation propertiesFatigue resistance

Flame Retardant Black (Arkema FR512)

This material is a flame-retardant resin that achieves a UL-94 rating of V-0 at 0.031 in. (0.8mm) while maintaining good print accuracy with fine feature parts.

Primary Benefits

High strength and heat deflection temperature (HDT)Liquid at room temperature

Robust printing and processing

Compare Material Properties

| US | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Metric | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Surface Finish on HPS Parts

Unfinished

Dots, or standing nibs, remain evident on the bottom of the part from the support structure remnants.

Natural (Default)

Supported surfaces are sanded down to eliminate support nibs.

Standard

Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present.

Custom

Secondary options include a primer or paint that can be applied as well as taps and inserts.

Surface Finish on Carbon DLS Parts

Shown below is a Carbon DLS part built with RPU 70 Rigid Polyurethane in normal resolution (0.004 in.).

Unfinished

With unfinished, you get varying aesthetics based on build orientation. Dots or standing nibs remain evident on the bottom of the part from the support structure remnants.

Natural Finish

With natural finishing, you get varying aesthetics based on build orientation. Standing nibs are sanded flat.

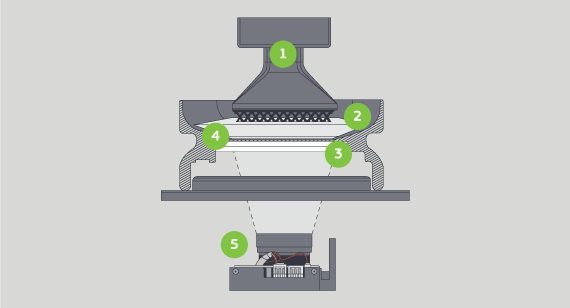

How Does HPS Work?

One answer is fast—really fast. Two established technologies team up to create a sum that is greater than its parts. Like XS, light is used to quickly harden liquid resin to create various geometries. HPS takes it a step further by adding a laser (as with SLA) to add precision and speed. When one layer is complete, the build platform rises and the process repeats until the part is complete. In the end, you get both the speed of XS, and feature details, resolution, and build volume of SLA.

How Does Carbon DLS Work?

XS uses CLIP (continuous liquid interface production) technology to produce parts through a photochemical process that balances light and oxygen. It works by projecting light through an oxygen-permeable window into a reservoir of UV-curable resin. As a sequence of UV images are projected, the part solidifies, and the build platform rises.

At the core of the CLIP process is a thin, liquid interface of uncured resin between the window and the printing part. Light passes through that area, curing the resin above it to form a solid part. Resin flows beneath the curing part as the print progresses, maintaining the continuous liquid interface that powers CLIP. Following the build, the 3D-printed part is baked in a forced-circulation oven where heat sets off a secondary chemical reaction that causes the materials to adapt and strengthen.