CNC Machining Materials

Metals

Aluminum

Copper

Stainless Steel

Titanium

Plastics

ABS

Delrin

Nylon

PEEK

Looking for additional metals like Inconel, Invar, or magnesium? How about plastic like fiber epoxy or Garolite? Check out XS Network.

Factory vs. Network

We offer a range of capabilities through our in-house digital factories at XS along with our digital network of manufacturers. If speed is essential, our factory capabilities have you covered, but if you're in need of advanced capabilities and have more flexibility in your schedule.

| | Factory Capabilities | Network Capabilities |

|---|---|---|

| Maximum Part Size | 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.3mm) | 25.5 in. x 25.5 in. x 11.8 in. (650mm x 650mm x 300mm) |

| Minimum Part Size | 0.25 in. x 0.25 in (6.35mm x 6.35mm) | 0.019 in. (0.50mm) |

| Tolerances | +/- 0.005 in. (+/- 0.13mm) | +/-0.001 in. (0.020mm) |

| Radii | Sharp inside corners on a part will be radiused (rounded) as a natural result of the CNC machining process. | |

| Text | Plastic and soft metals: Minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). Example text size would be 16 point Arial Rounded MT font. | |

| Text | Hard metals: Minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). Example text size would be 22 point Arial Rounded MT font. |

| | Factory Capabilities | Network Capabilities | |

|---|---|---|---|

| Maximum Dimensions | Diameter | 3.95 in. (100.33mm) | 17 in. (431mm) |

| Length | 9 in. (228.6mm) | 39 in. (990mm) | |

| Minimum Dimensions | Diameter | 0.16 in. (4.07mm) | 0.039 in. (1mm) |

| Length | 0.05 in. (1.27mm) | 0.019 in. (0.5mm) | |

| Wall Thickness | 0.020 in. (0.51mm) | 0.019 in. (0.5mm) | |

| Angle | 30° | Below 90° | |

| Tolerances | +/- 0.005 in. (+/- 0.13mm) | ±0.001 in. (0.020mm) |

Note: Small features may be allowed, but the diameter in any region should not be less than 0.030 in. (0.76mm). Sharp conical points are allowed; angles should be greater than 30 degrees. Walls thinner than 0.020 in. (0.5mm) typically do not survive the machining process.

Tolerances for CNC Machining

We offer a wide range of tolerances for CNC machined parts to fit your project priorities.

Note: Small features may be allowed, but the diameter in any region should not be less than 0.030 in. (0.76mm). Sharp conical points are allowed; angles should be greater than 30 degrees. Walls thinner than 0.020 in. (0.5mm) typically do not survive the machining process.

Surface Finish and Post-Processing Options

XS offers a variety of CNC machining surface finishing options to meet your part requirements. More advanced coating and plating options are also available.

Surface Finish Options:

- Edges broken with tool marks visible

- Edges broken with light bead blasting

- Sharp edges (tool marks visible)

Coating and Plating Options:

- Anodizing

- Chromate coating

- Powder coating

Why Choose Us for Custom CNC Machining?

Fast and Reliable Delivery

Iterate part designs quickly and accelerate product development with quick-turn parts. Our automated design analysis will help spot any difficult to machine features before your design is sent to the manufacturing floor and save you from costly reworks further down the product development cycle.

Manufacturing Analysis and Online Quotes

When you upload your 3D CAD file to request a quote, we'll analyze your part geometry to identify any features that may be difficult to machine such as tall, thin walls or holes that cannot be threaded.

Domestic Production and Support

Work with a trusted U.S.-based manufacturer and eliminate the risk of sending parts overseas. You can also call or email us at any time and we'll help with ordering parts, design feedback, material recommendations, and answer any questions.

Infinite Capacity

Eliminate downtime spent waiting for parts and safeguard in-house machining with on-demand relief and infinite manufacturing capacity.

Material Selection

We stock more than 30 engineering-grade plastic and metal materials that are suitable for various part applications and industries. Materials range from plastics like ABS, polycarbonate, nylon, and PEEK to aluminum, stainless steel, platinum, and copper.

Advanced Capabilities

Get anodizing, tighter tolerances, and volume pricing options through Protolabs Network. You'll find plating (black oxide, nickel), anodizing (Type II, Type III), and chromate coating in larger part quantities; tolerances down to ±0.001 in. (0.020mm); and cost-efficient machined parts at higher volumes to lower piece-part price.

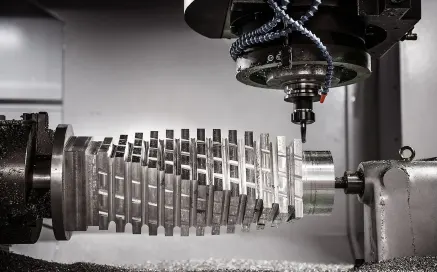

Advantages of CNC Machining

The subtractive process of CNC machining provides multiple benefits for both prototyping and production parts.

- Precision and repeatability

- Tight tolerances

- Production-grade materials

- Quick-turn parts within 1 day

- Lower piece-part price at higher quantities

- Robust post-processing to improve cosmetics and material properties

CNC Machining Applications

CNC machining is widely used throughout the aerospace, medical, automotive industries for its ability to rapidly manufacture precise parts in production-grade materials. Typical CNC parts, include:

- Housings and enclosures

- Brackets

- Fixtures for manufacturing

- Gears and bearings

- Internal mechanical components

- Medical instrumentation

Get an Instant CNC Machining Quote

Upload a 3D CAD file of your machined part and within a few hours we'll send you manufacturing analysis and an interactive quote. Within your quote you can modify materials and quantities and see pricing updates in real-time. Additionally, within your manufacturing analysis, you can assign threading with a click of your mouse.

Tour Our CNC Machine Shop

Take a quick tour through our 215,000 sq. ft. CNC machining facility to see how we leverage digitally-enabled processes to achieve industry-best lead times.