Jump to Section

→ Capabilities

→ Materials

→ Surface Finishes

→ Tour Our Machine Shop

→ About CNC Milling

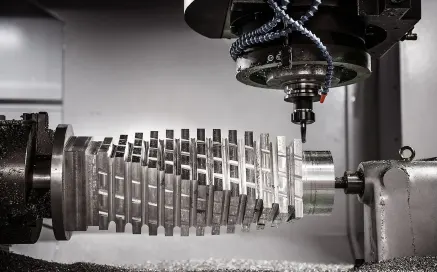

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals. With machined production parts, you can also get more competitive pricing at higher quantities in addition to first article inspection (FAI) reporting, material certifications, and additional finishing options like anodizing and chromate plating.

Our CNC milling service is commonly used for:

- functional prototypes

- jigs and Fixtures

- production components in lower volumes

CNC Milling Design Guidelines and Capabilities

Our basic guidelines for CNC milling include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. View our design guidelines page for more details.

| Maximum Dimensions | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Maximum DimensionsMaximum depth that can be milled is 2 in. (50.8mm) from either side of part. For specific milling dimensions by material, see maximum part extents for machining.

**Denotes two-sided machining only |

| Minimum Dimensions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Minimum Dimensions

|

| Threading |

|---|

ThreadingWe currently support UNC and UNF threads from #2 up to 0.5 in., and metric threads from M2 to M12. Avoid modeling internal threads on your part design. We also offer the following for milled parts:

|

CNC Milling Materials

We stock more than 30 production-grade plastic and metal materials that are suitable for various part applications and industries.

Plastics

|

|

- Aluminum

- Brass

- Copper

- Stainless Steel

- Alloy Steel

- Steel Mild Low Carbon

- Titanium

Anodizing and Chromate Plating Specifications

| Anodize | Hard Anodize | Chromate |

|---|---|---|

|

MIL-A-8625 Type II, Class 2 (Blk) MIL-A-8625 Type II, Class 1(Clr) |

MIL-A-8625 Type III, Class 2 (Blk) | MIL-DTL-5541 Type II, Class 3 (Clr) |

Quick-turn Finishing

Here are the requirements to get parts in as fast as 4 days (1-day expedite + 3 days for plating):

High-requirement Finishing

Have AS9100 and ITAR requirements? Try our domestic precision machining option. If you have more complex anodizing and plating requirements, work with our digital network of manufacturers. The network works well for components that require a specialized color or material option such as titanium or nickel.

Surface Finish on Milled Parts

Typically, we break (debur) the edges on all machined parts. All machined plastic parts are left as-machined, which may leave visible tool marks. Some metal parts, on the other hand, allow more choice. Parts left with sharp edges should be handled with care.

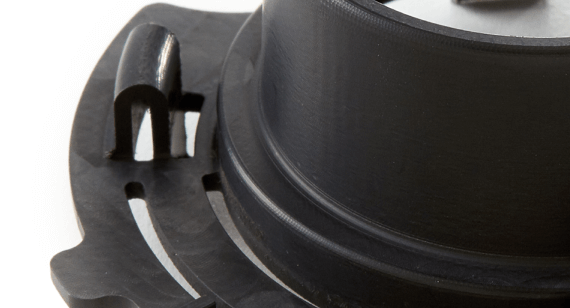

Material: ABS Black Finish: Broken edge

Material: ABS Natural Finish: Broken edge

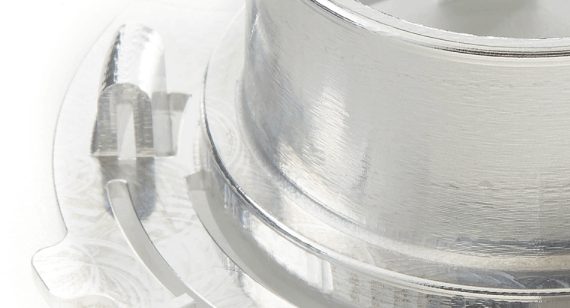

Material: Aluminum Finish: Broken edge

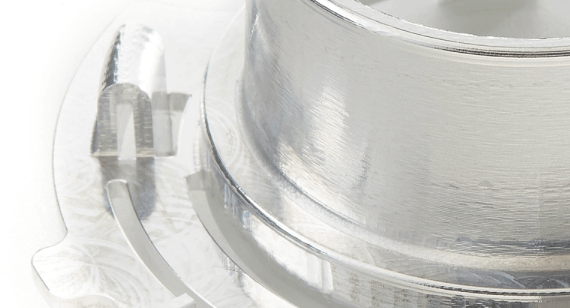

Material: Aluminum Finish: Bead Blast