Want to shorten production cycles and reduce costs for mechanical components?

Characteristics and Advantages of CNC Machining for Die Castings

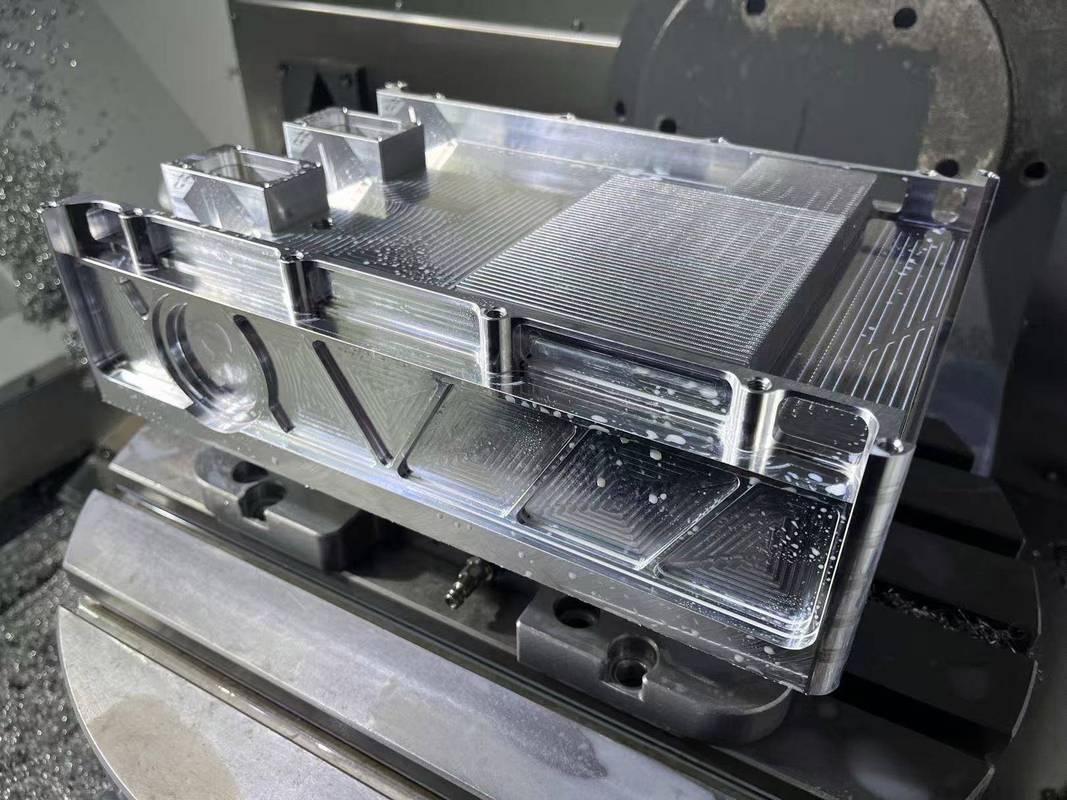

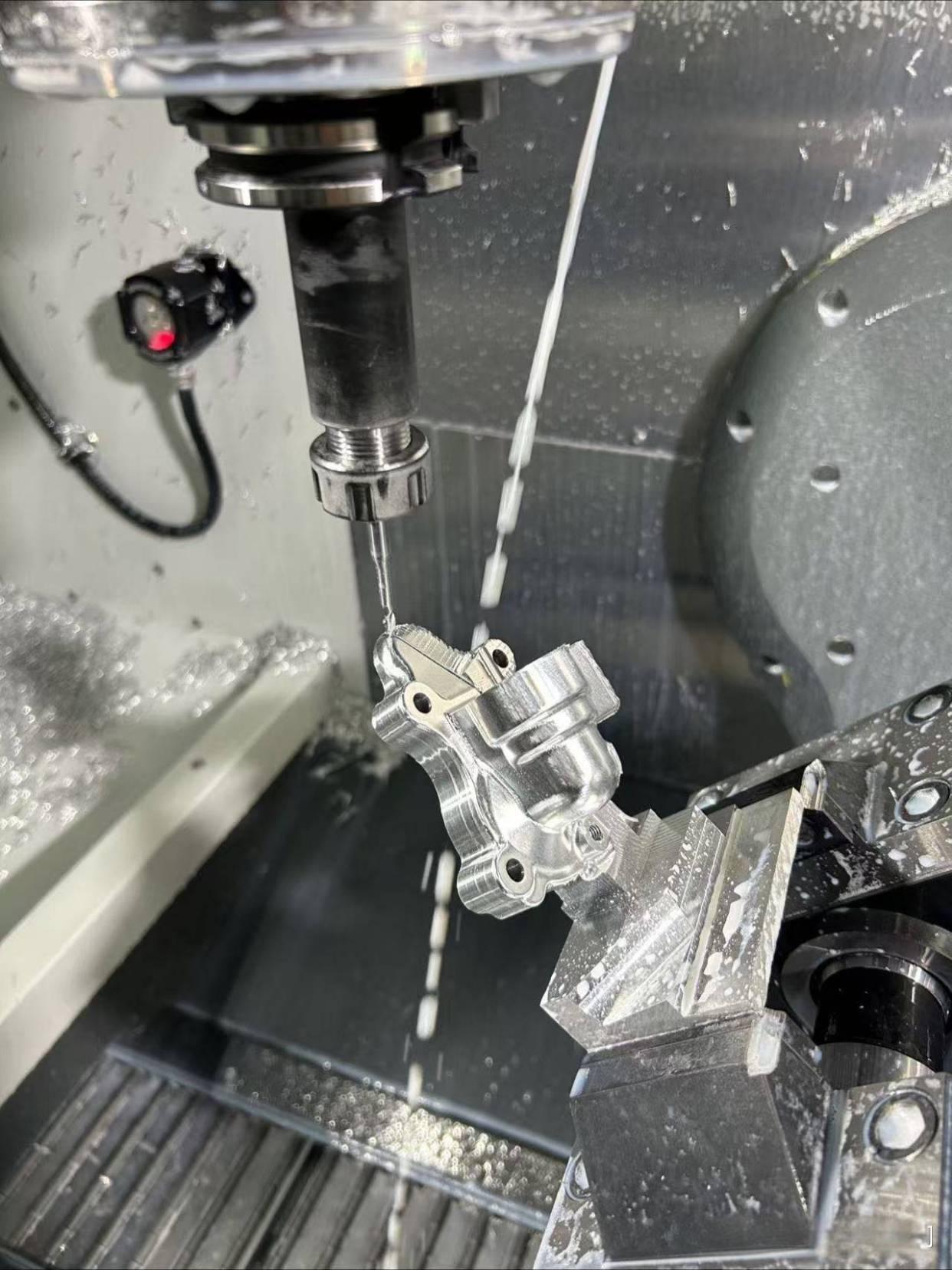

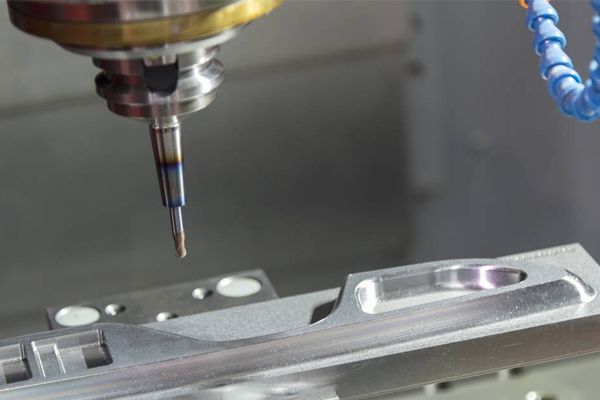

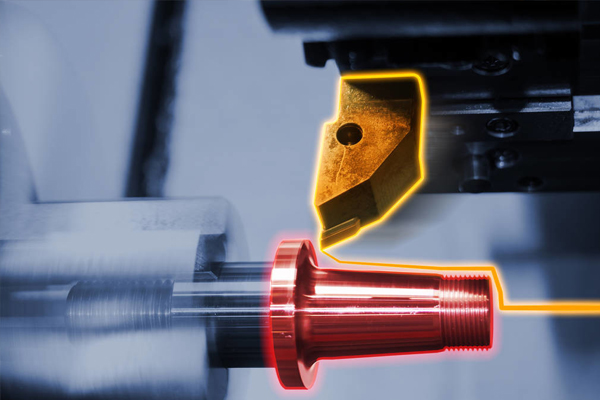

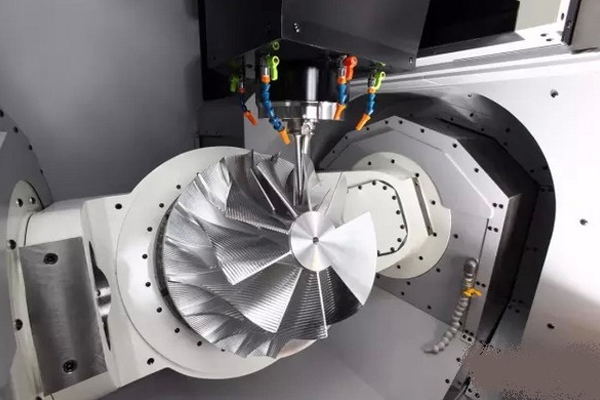

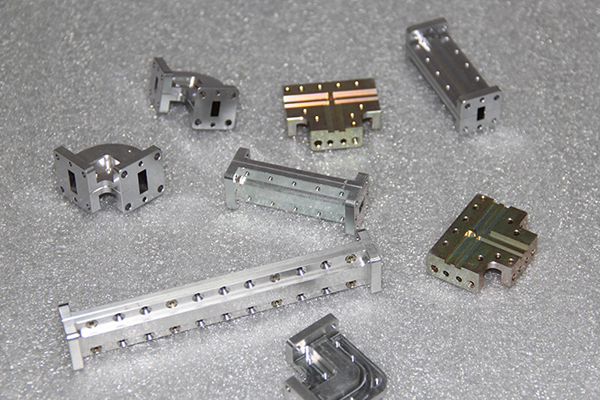

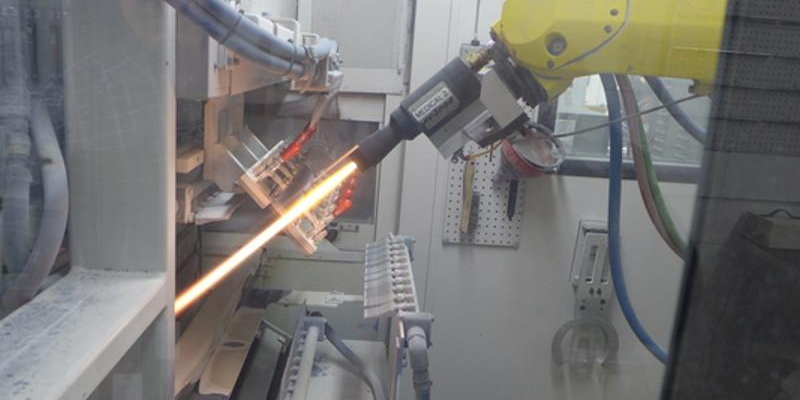

CNC machining for die castings leverages computer numerical control (CNC) technology to achieve precision finishing of die - cast components. While die casting excels at mass - producing complex thin - walled parts, it has limitations in dimensional accuracy and surface finish, necessitating CNC machining to enhance quality. CNC processes remove material layer by layer, enabling highly customized designs with intricate details. This method achieves superior precision in micro - features and complex internal channels. Post - processed components can undergo various surface treatments, such as polishing and anodizing. By integrating the high efficiency of die casting with the precision of CNC machining, this hybrid process is widely adopted in industries including automotive, aerospace, and electronics.

CNC Machining Service Capabilities

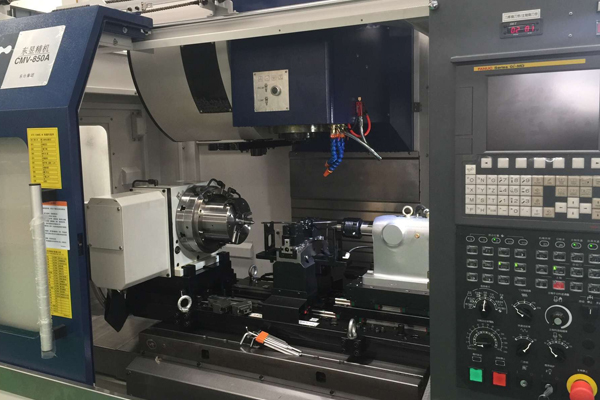

XS can meet your needs for CNC machined parts, ranging from rapid prototyping to precision part and mold machining, and on to end - use production.

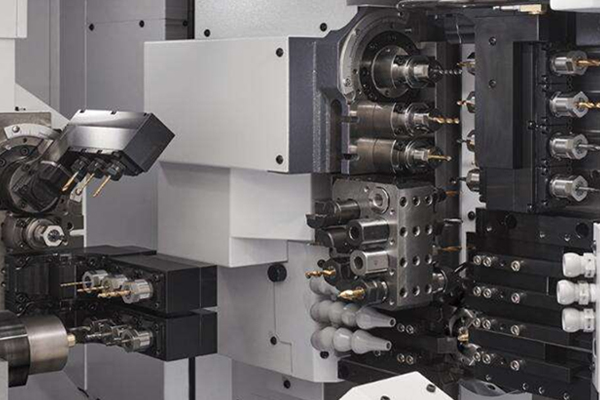

CNC Milling

CNC Turning

Machining

5 - Axis Machining

Vertical Machining

Horizontal Machining

Conventional Alloys

Superalloys

Plastic Processing

Surface Treatment

Painting

Passivation

Electroplating

Powder Coating

Anodizing

Polishing

Black Oxide

Conversion Coating

Bead Blasting

Sand Blasting

Thermal Spraying

Surface Hardening

Advantages of XS CNC Machining Services