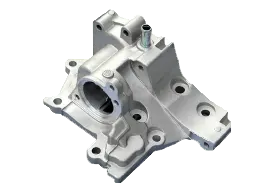

Post-Casting CNC Machining

5-axis machining centers for complex geometries

XS Die Casting Capabilities

Factory vs. Network

We offer a range of capabilities through our in-house digital factories at XS along with our digital network of manufacturers. If speed is essential, our factory capabilities have you covered, but if you're in need of advanced capabilities and have more flexibility in your schedule.

High Pressure Die Casting

Low Pressure Die Casting

Hot and Cold Chamber Die Casting

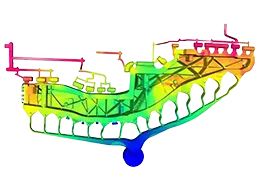

Advanced Modeling and Design Software

Download our Die Casting Design Guide

Learn our top tips for design, material selection, geometric features, tolerance, and more.

Post-Casting CNC Machining

5-axis machining centers for complex geometries

Post-Casting CNC Machining

5-axis machining centers for complex geometries

High vs Low

Pressure

Die Casting

| Low Pressure Die Casting | VS | High Pressure Die Casting |

|---|---|---|

| Typically 5-30 PSI | Injection Pressure | Typically 1,000-20,000 PSI |

| Slow | Injection Speed | Comparatively Fast |

| ✔ | Faster Cooling Rate | |

| Lower Secondary Dendrite Arm Spacing | ✔ | |

| >0.18 inches | Recommended Wall Thickness Range | 0.08 to 0.16 inches |

| ✔ | Higher Dimensional Accuracy | |

| Yes | Undercuts | No |

| ✔ | Better Suited for Complex Geometries |

Prototype Die Casting

Production Die Casting