XS Platform enables an endless combination of processes, materials and finishes. Here are some commonly used by our customers in the Automotive and EV industries:

CNC Machining

Tight tolerances and finishing capabilities, as fast as 1 day.

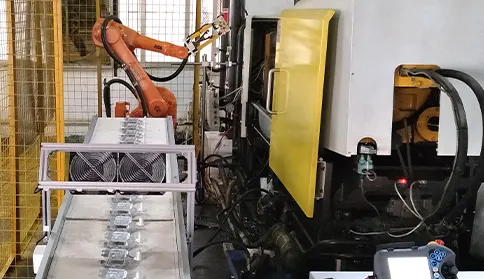

Injection Molding

T1 samples as fast as 10 days withlow minimum order quantities.

Sheet Metal Processing

0.1mm precision shapes metal aesthetics.

Die Casting

Create high quality custom mechanicals with precision and accuracy.

Automotive and EV Manufacturing from Prototype to Production

XS provides a streamlined supply chain for everything from prototype to test units to start of production and beyond.

Prototype

Rapid turn-around times for early stage designs with a wide range of 3D printing technologies and urethane casting.

Proof of functionality before investing in tooling

Urethane Casting In a Variety of Materials

Attractive looks-like models

Design Validation Testing

Validate part strength, functionality, and aesthetic finish with production-grade injection molding at prototype speeds and CNC machining with a wide range of finishing options.

High quality parts for testing strength and functionality

Rapid Design Molds with steel tooling at low quantities

Validate appearance and durability of surface finish

Variety of post-processing options available for CNC Machined parts

Engineering Validation Testing

Iterate quickly on high-precision, functional prototypes with tight-tolerance CNC Machining, Gear Hobbing, and rapid Injection Molding with steel tools.

Optimize material properties for your design

Wide selection of materials available for CNC Machining

Precision gear manufacturing

High quality design options for Design of Experiments

Rapid Design Molds with steel tooling at low quantities

Production Validation Testing

Prepare your designs for scale, with production-grade manufacturing capabilities at low volumes and advanced quality control services with transparent documentation.

Rapid delivery of production level parts to validate manufacturing process

Production Tooling at low volumes

Tight tolerances on precision parts at bridge production quantities

Precision CNC Machining with tolerances as tight as +/- 0.0002 in

Tight tolerances on precision parts at bridge production quantities

Precision CNC Machining with tolerances as tight as +/- 0.0002 in

Production

Seamlessly transition into production, with end-use parts delivered rapidly and adoption of your precise quality requirements into the XS manufacturing system.

Manufacturing line fixtures

Quick-turn CNC machining

Scale up to production level quantities quickly

Production tooling with multi-cavity and family tools

Custom quality inspection plans and volume discounts

Available with XS Rapid

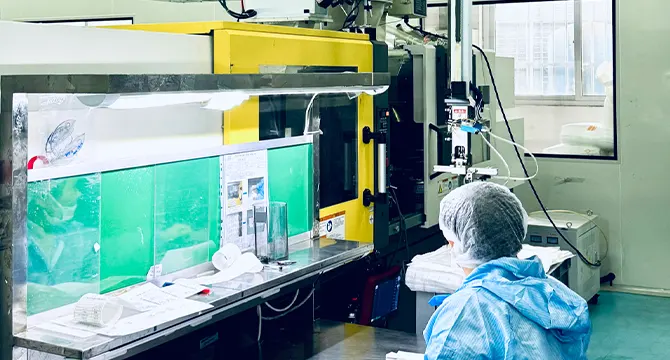

Medical Device Injection Molding

Our medical molding service allows you to leverage the speed-in-development you are used to in the high-requirement environment of the medical space. Our team of medical molding manufacturing experts helps you take FDA Class I and II devices, or non-implantable components, quickly from prototype to production and is viable through regulatory body submissions.

A Guide to Manufacturing Aerospace Parts

The aerospace and defense industry is known for producing complex and advanced products—jet engines, aircraft, rockets, satellites, drones, and more—that move fast in a highly regulated environment. It is no wonder that these factors of speed, complexity, and policy compliance play key roles in the manufacturing process.

Resources for Automotive Engineers

Start Your Next Project Today