Jump to Section

→ Build Sizes

→ Our Large Format 3D Printers

→ Part Bonding

Large format 3D printing is used for large, complex geometries and reducing multipart assemblies into a single design. 3D print metal parts as large as 31.5 in. x 15.7 in. x 19.7 in. and plastic parts as large as 29 in. x 25 in. x 21 in.

“I haven't found a better process out there that makes executing a 3D printproject any easier.

- TYLER KICER AKOLLAB

Maximum Part Sizes for Large Format 3D Printing

| Material | Build Size | ||

|---|---|---|---|

| Metal | Aluminum (AlSi10Mg) | 31.5 in. x 15.7 in. x 19.7 in. | 400mm x 800mm x 500mm |

| Inconel 718 | |||

| Plastic | ABS-Like White | 29 in. x 25 in. x 21 in. | 736mm x 635mm x 533mm |

| ABS-Like Gray | |||

| ABS-Like Translucent/Clear | |||

| PC-Like Translucent/Clear | |||

| PA 12 | 19 in. x 19 in. 17 in. | 482mm x 482mm 431mm | |

Large Format Metal 3D Printer

For large metal parts, we use the Concept Laser X Line 2000R 3D printer. This machine provides a build volume of 400 x 800 x 500 mm. The X Line 2000R was designed specifically for the production of large, quality parts.

Large, 3D-printed parts are often used in industrial settings, aerospace applications, automotive, and energy.

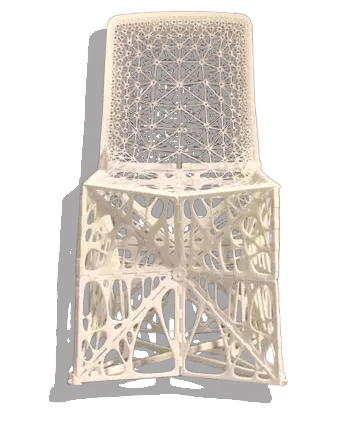

Large Format Plastic 3D Printing

Stereolithography (SLA): Large SLA parts are built on 3D System iPros, which provide large build volume, while still producing detailed parts.

Selective Laser Sintering (SLS): For large parts built in PA 12, we use sPro140 machines.

Bonding for Large Plastic Parts

Need a part that exceeds our machine's build volume? Part cutting and bonding is available for SLA, SLS, and MJF to achieve even larger part sizes.

Wall thickness needs to be sufficient for a good cut. For large geometries we need a minimum of a 0.1” (2.54mm) or 0.12” (3mm) thick wall to get a decent cut. Keep in mind, the thicker the better to achieve the best cut. If a part is too large to print in one piece then you will likely want to have thick walls regardless to overcome potential part warpage.

The cutting and bonding process will leave stark visible seams at the cut and bond interface. These can be unsightly, but may be allowable if you are using the part for function only. If the part is meant to be aesthetic, custom finishing can be performed to smooth, fill, prime, and paint the bond interface seams. Note, this is difficult to achieve with functionally clear parts.