Jump to Section

→ Our Process

→ Design Guidelines

→ Materials

→ Laser Cutting Applications

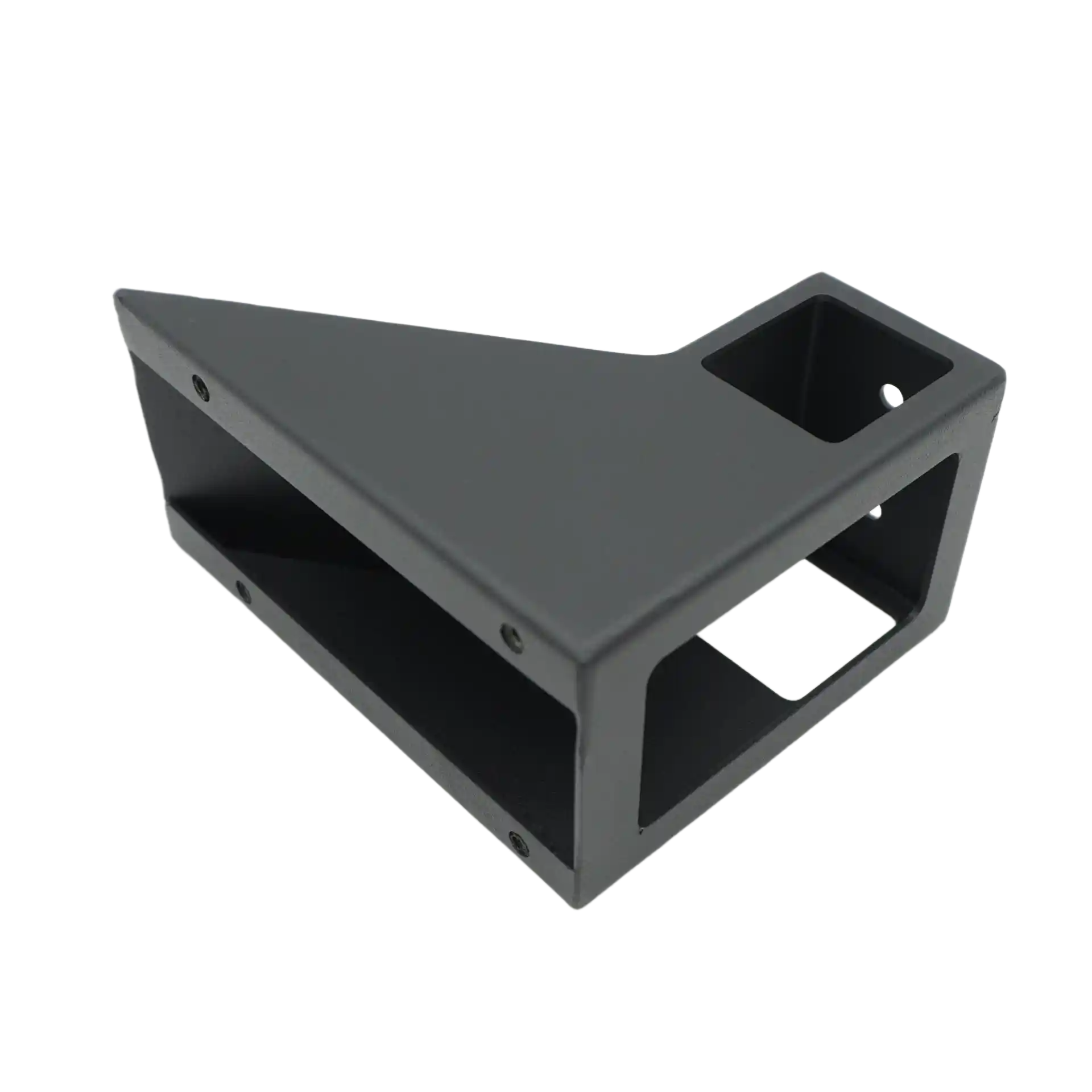

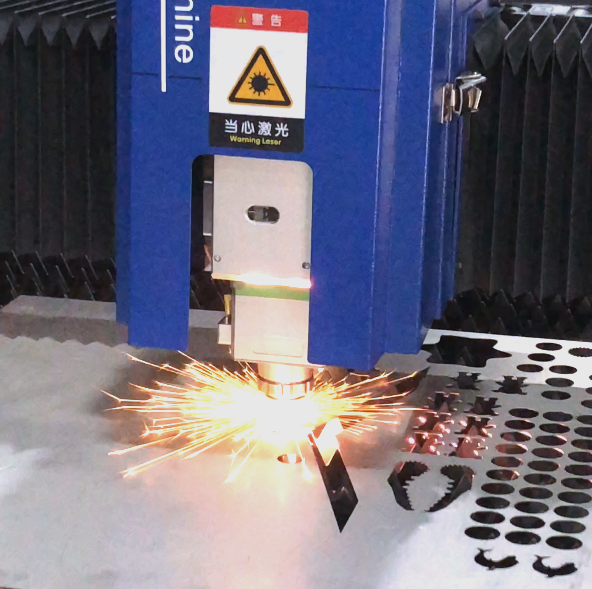

Laser cutting is a manufacturing process where a laser beam pierces raw sheet stock to produce flat geometries. A range of metals are available, which work well for components such as washers, mounts, brackets, and housings.

Laser cutting is commonly used for:

- prototyping designs or testing product requirements

- efficiencies of scale up to 50+ parts

- parts with standard connectivity features (USB, HDMI, ethernet ports)

Our Laser Cutting Process

Our laser cutting service and capabilities are designed around reliably producing quality parts on time.

Configure materials, finishes, and additional options in myRapid

Standard 3-day lead times for quantities less than 50

Process ensures parts are safe to handle out of the box

Basket of sheet metal components ship on same standard lead time

Flatwork and formed parts produced with one supplier

Laser Cutting Design Guidelines

Follow these guidelines for flat, laser cut parts to ensure quality and accelerate production time.

| in. | ||||||||

|---|---|---|---|---|---|---|---|---|

|

| mm | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Materials and Thicknesses for Laser Cut Parts

We offer the following metal materials for custom laser cut parts. Note that based on material thickness, maximum part size will vary.

| Material | Grade | Thicknesses Available |

| Aluminum |

|

0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| Steel |

|

0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| Stainless Steel |

|

0.025 in. - 0.250 in. (0.635mm - 6.35mm) |

| Copper |

|

0.025 in - 0.125 in. (0.635mm - 3.175) |

| Brass |

|

0.025 in. - 0.125 in. (0.635mm - 3.175) |

Applications for Laser Cut Parts

Laser cutting is a frequently used manufacturing process in industries such as energy storage, computer electronics, robotics, and aerospace. Common parts fabricated with laser cutting include:

- flat patterns

- face plates

- washers

- mounting plates

- panels