Quality is in Our Work Standards,and Our DNA

Our dedication to quality is apparent throughout the manufacturing process, and you’ll experience it from your first interaction. When you submit a CAD file for a quote, you’ll receive analysis of your design.

Our automated design for manufacturing analysis quickly identifies potential issues, such as:

- Walls that are too thin

- Parts that are too large

- Holes that are eligible for threading

If you get one of these advisories, you will also notice that it includes a proposed solution to fix your model. With a single click, you can choose to accept the issue and proceed as-is or go back to redesign and resubmit your model.

Dedicated to Delivering Quality

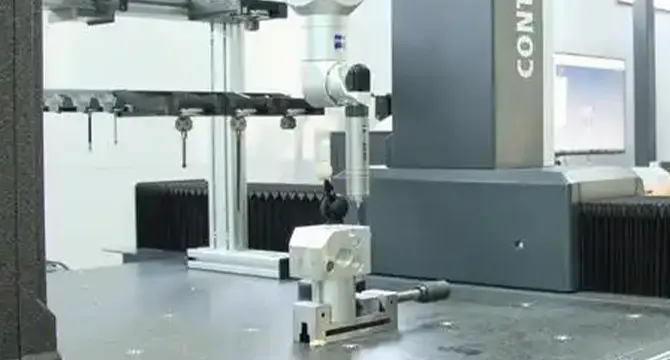

Our mission is to deliver great parts every time. To do that, we use clearly documented work standards and procedures. To minimize escapes, our proprietary software instructs our factory CNC machines to perform in-process quality checks on every unique geometry. Whether produced in our factories or through XS Network, once the part is completed, our quality control experts take over and visually and dimensionally inspect the physical part to ensure consistency with your 3D model (or print, if necessary).

Inspection Documentation for CNC Machining Projects

You can choose from multiple forms of quality inspection documentation for your CNC-machined part orders based on the complexity of your models. Depending on your project requirements, the following reports are available within your online quote. Additionally, you can request Certificates of Conformance, Material Certifications, and Hardware Certifications.

- Basic Production/Quality Inspection Report

- Dimensional Inspection Report

- First Article Inspection

- Production Part Approval Process (PPAP)

Quality Inspections for CNC Machining

| Inspection without Report | Basic Production/Quality Inspection Report | Dimensional Inspection Report | First Article Inspection | |

|---|---|---|---|---|

| Benefits | Parts are inspected dimensionally and visually, A Certificate of Conformance is available, but measurement results are not included. | Parts are inspected dimensionally and visually. An inspection report with corresponding measurements is included. | Verifies numerous dimensional specifications without requiring a 2D drawing for precision machined parts. Quick-turn parts require a 2D drawing. GD&T is not inspected. | Verifies the sample part conforms to all dimensions provided on a 2D drawing, including GD&T. Results provided in AS9102 format. |

*Note that capabilities may vary by manufacturing site

Support from CNC Machining Experts

Discuss your design with a CNC machining applications engineer who can answer any manufacturability questions you might have. Common design review topics include optimizing cost, tolerances, threading, and finishing options.

Machined Parts for Aerospace Applications

With capabilities such as AS9100, FAI, material traceability, NADCAP-certified coatings, and full technical drawing and quality requirement reviews, we can get your parts to you, as designed, in as little as 1 business day. This reduces time for iteration and speeds your transition to final part designs, both critical needs for the aerospace industry.

Learn More