Choose a Manufacturing Service

Enhanced Manufacturing Capabilities with Our Digital Network

Injection Molding Materials

XS can mold any commercially available thermoplastic. Please reach out with your specific resin needs.

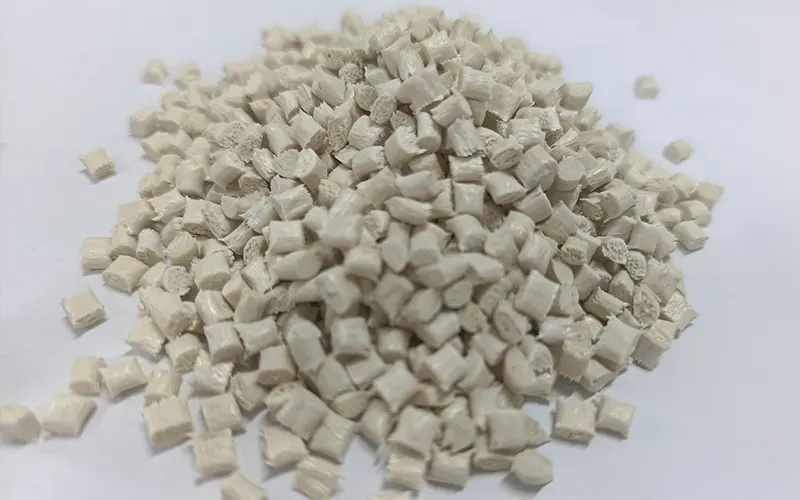

Acrylonitrile Butadiene Styrene

1.Mechanical properties: Medium to high strength, good impact resistance (notched impact strength up to 15-30 kJ/m²), with toughness superior to PS and PVC.

2.Heat resistance: The heat distortion temperature is approximately 80-105℃, and the short-term service temperature can reach 120℃.

Processability: Excellent fluidity, easy for injection molding, and capable of precise forming of complex structures.

3.Appearance: High surface gloss, which can be beautified by processes such as spraying and electroplating (e.g., automotive interior parts).

4.Chemical resistance: Resistant to fresh water, salt water, alkalis, and dilute acids, but not resistant to ketones, aromatics, and chlorinated hydrocarbons.

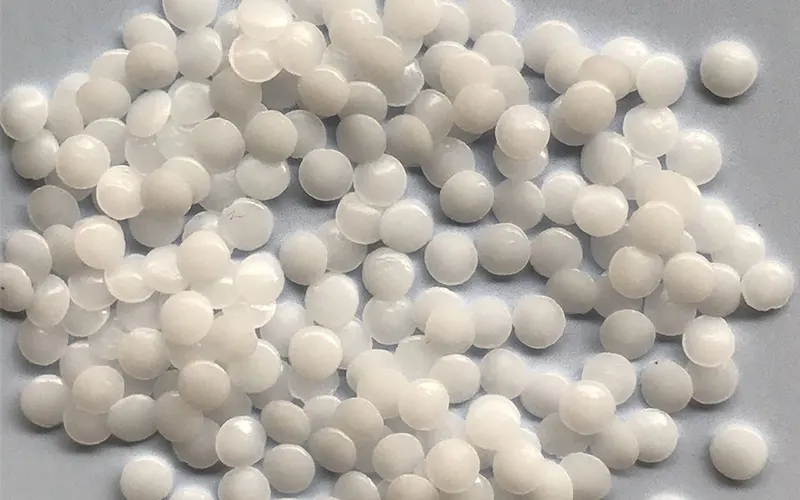

Polyethylene (PE)

Properties: Resistant to chemical corrosion, good flexibility, non-toxic and odorless, but poor heat resistance (maximum temperature about 80℃).

Applications: Food packaging, plastic bags, containers, toys, etc.

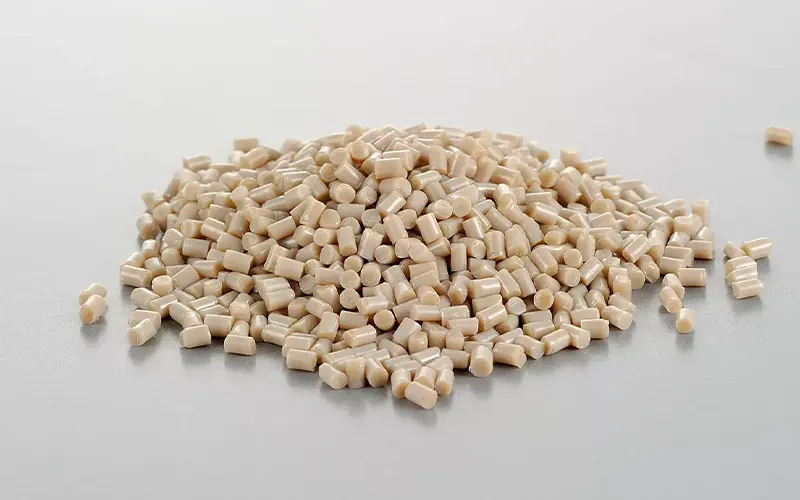

Polypropylene (PP)

Properties: Good heat resistance (can withstand 120-150℃), high hardness, resistance to bending fatigue, and strong chemical resistance.

Applications: Tableware, medical devices (such as infusion bottles), automotive components (bumpers), household appliance casings, etc.

Polyvinyl Chloride (PVC)

Properties: Low cost, good weather resistance, and divided into two types: flexible (with plasticizers) and rigid. Flexible PVC is pliable, while rigid PVC has high hardness.

Applications:

Flexible: Wire sheaths, hoses.

Rigid: Pipes, door/window profiles, sheets, etc.

Polyethylene Terephthalate (PET)

Properties: High transparency, high strength, excellent barrier property, resistant to acids and alkalis but not to hot water.

Applications: Beverage bottles (e.g., mineral water bottles), films, electronic component housings, etc.

Polyoxymethylene (POM)

Properties: High hardness, good rigidity, wear resistance, and strong dimensional stability, commonly known as "Delrin" or "acetal resin".

Applications: Precision mechanical parts (such as clock gears), automotive fasteners, medical devices, etc.

Polyphenylene Sulfide (PPS)

Properties: High temperature resistance (above 200℃), chemical corrosion resistance (strong acids and alkalis), and strong flame retardancy.

Applications: Electronic components (high-temperature sockets), automotive exhaust system parts, chemical equipment, etc.

Polyether Ether Ketone (PEEK)

Properties: Ultra-high-performance engineering plastic, featuring high temperature resistance (above 260℃), high strength, and excellent biocompatibility.

Applications: Aerospace components, medical implants (such as orthopedic prostheses), high-end electronic devices, etc.

Polycarbonate (PC)

Properties: High strength, high transparency, excellent impact resistance (raw material for bulletproof glass), and good heat resistance (120-130℃).

Applications: Optical lenses, automobile headlight covers, sports equipment, electronic device casings (such as mobile phone cases), etc.

Online Quoting and Manufacturing Analysis

We know the importance of having an optimized part design before any actual production begins, which is why we provide automated design for manufacturability (DFM) analysis within hours on every part that is uploaded.

Manufacturing Materials

Choose from hundreds of plastic and metal materials suitable for prototyping and end-use production applications.